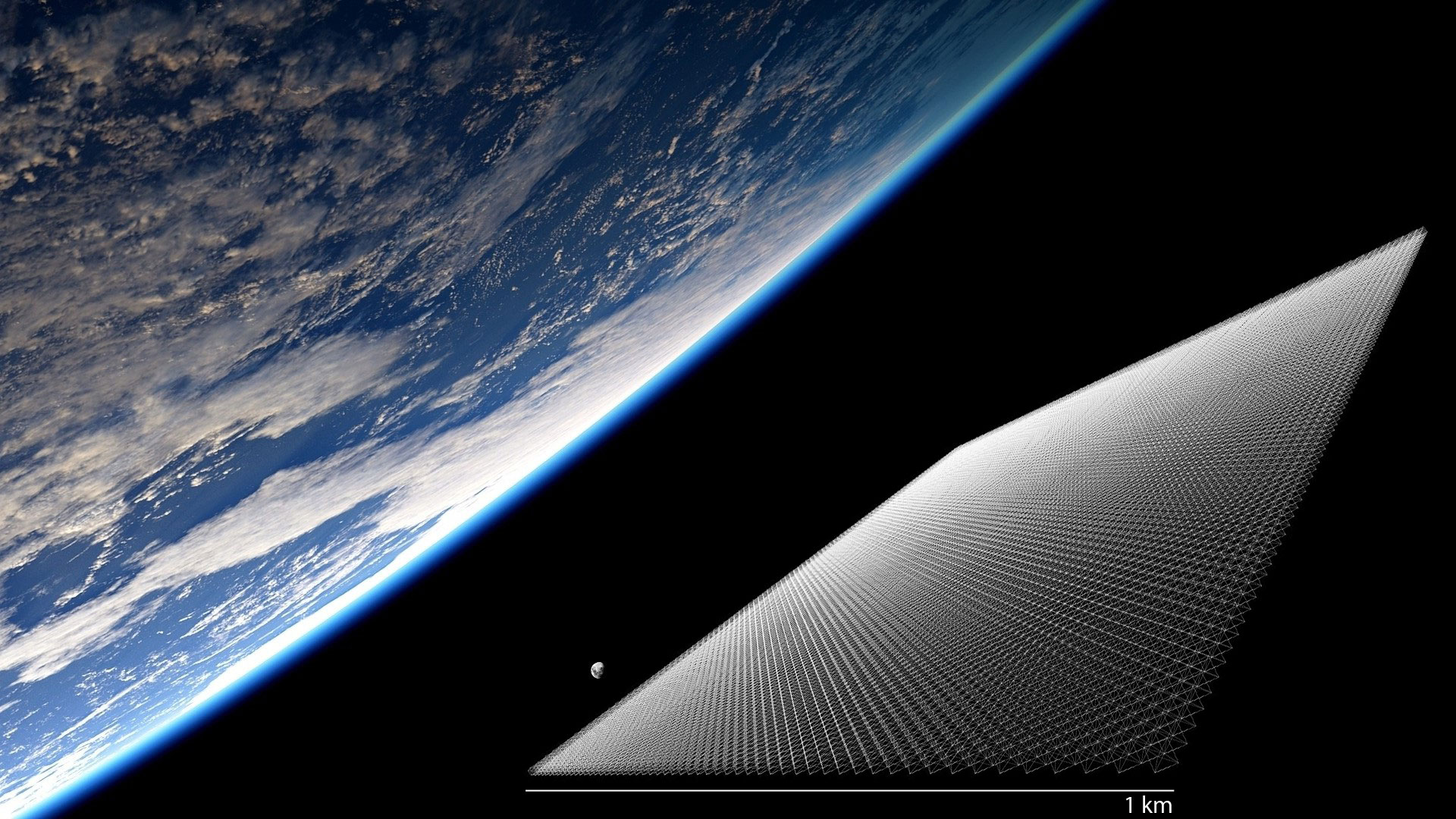

DMHSS: digital material

hierarchical space structures

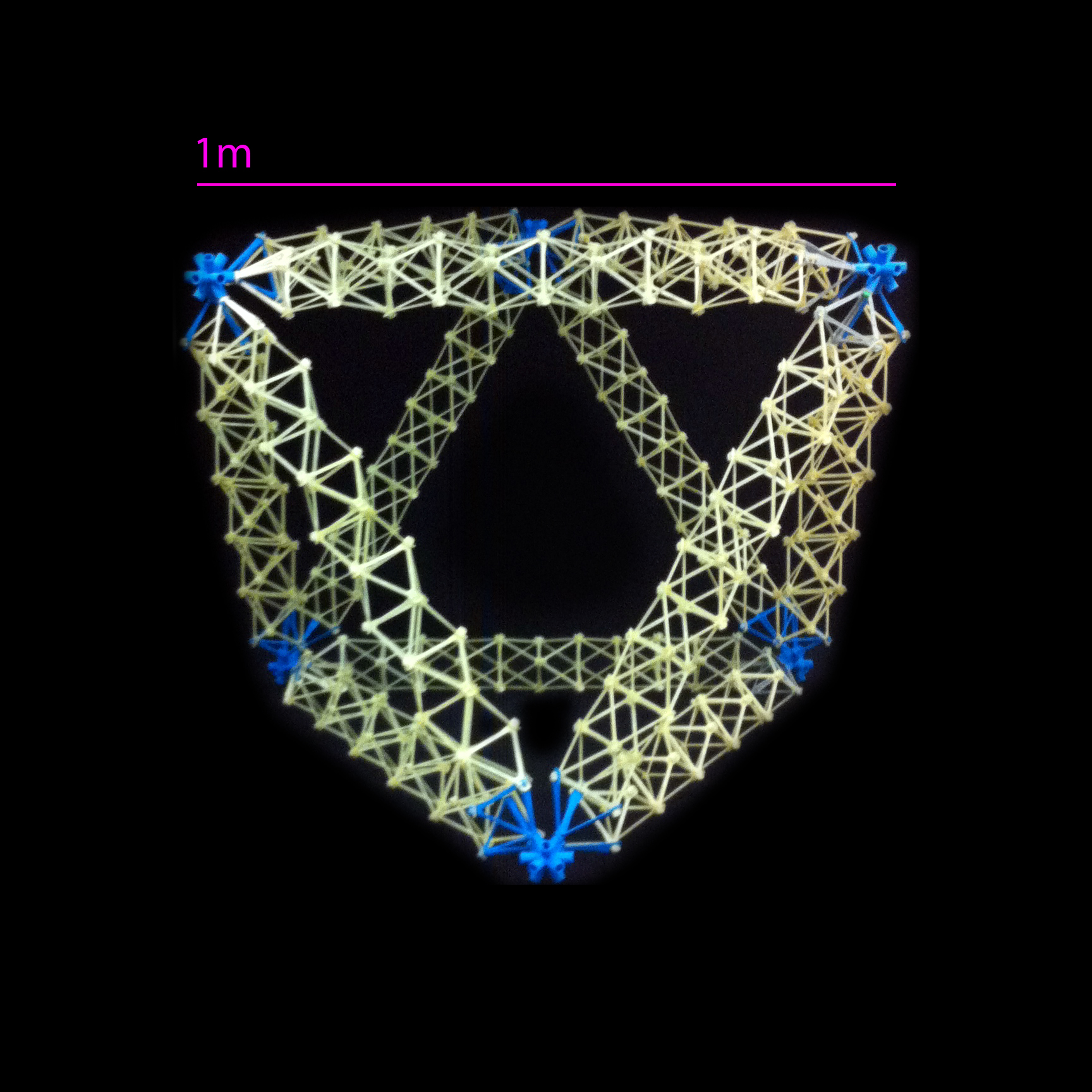

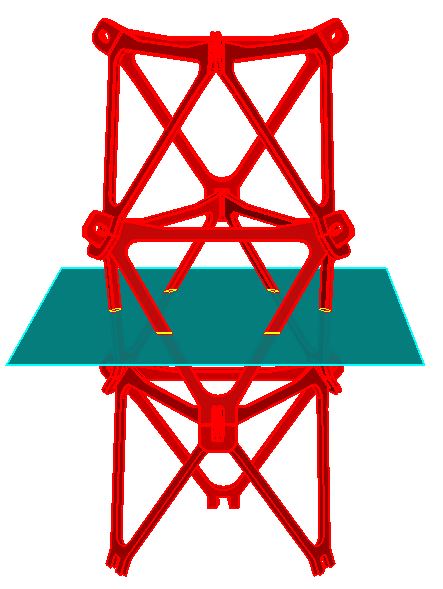

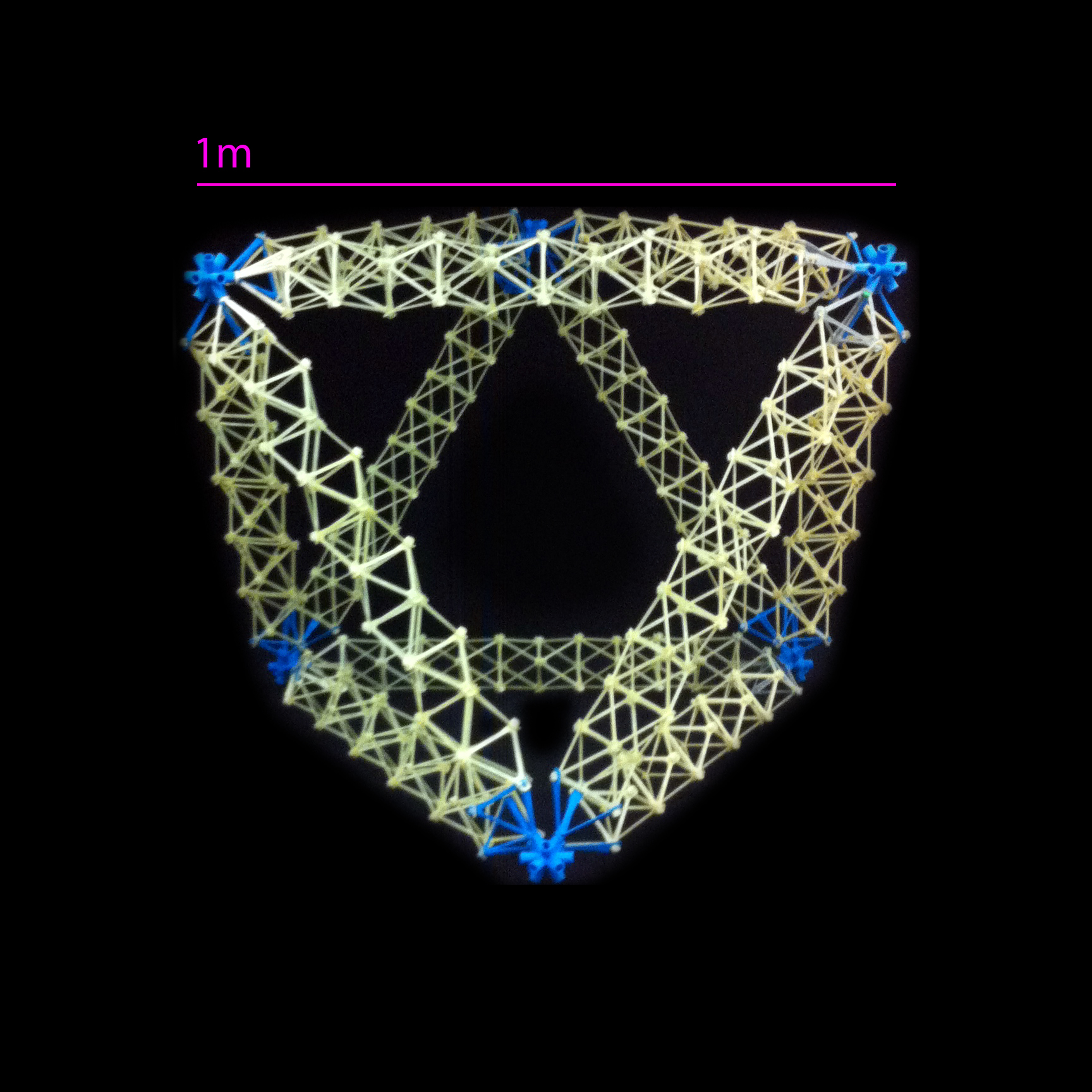

current hierarchical prototype

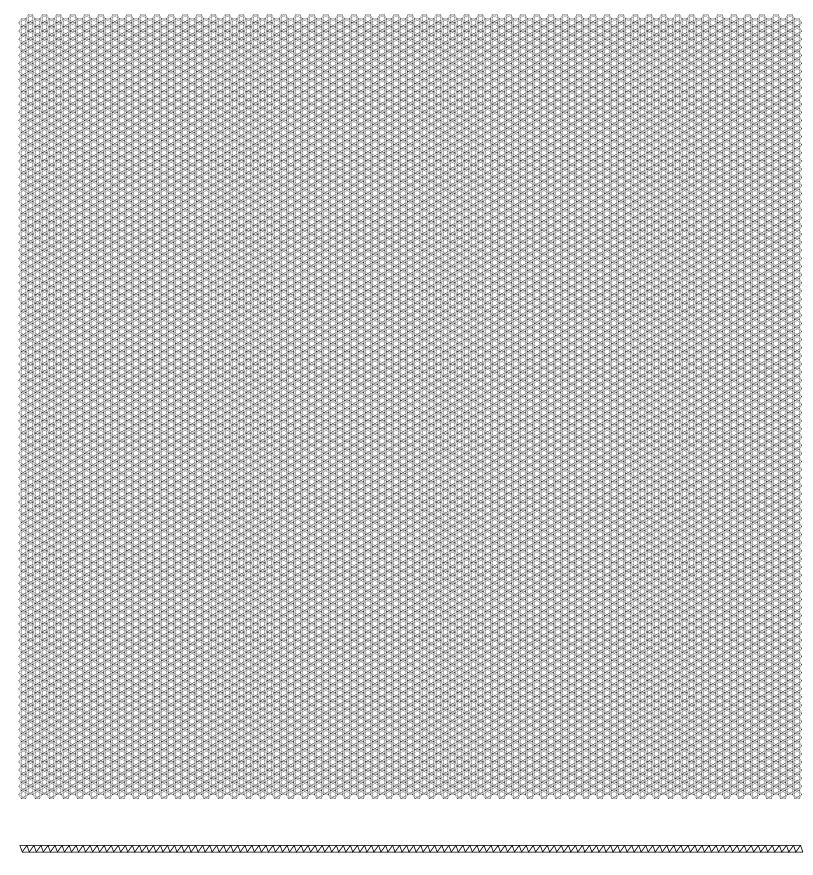

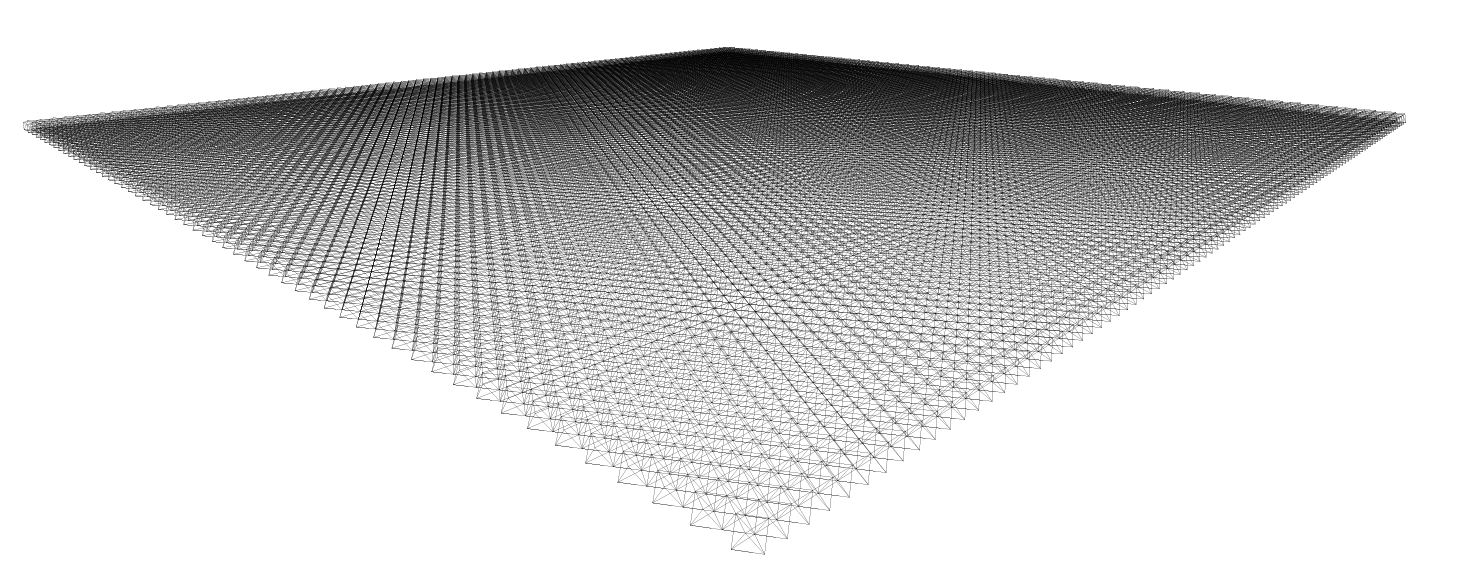

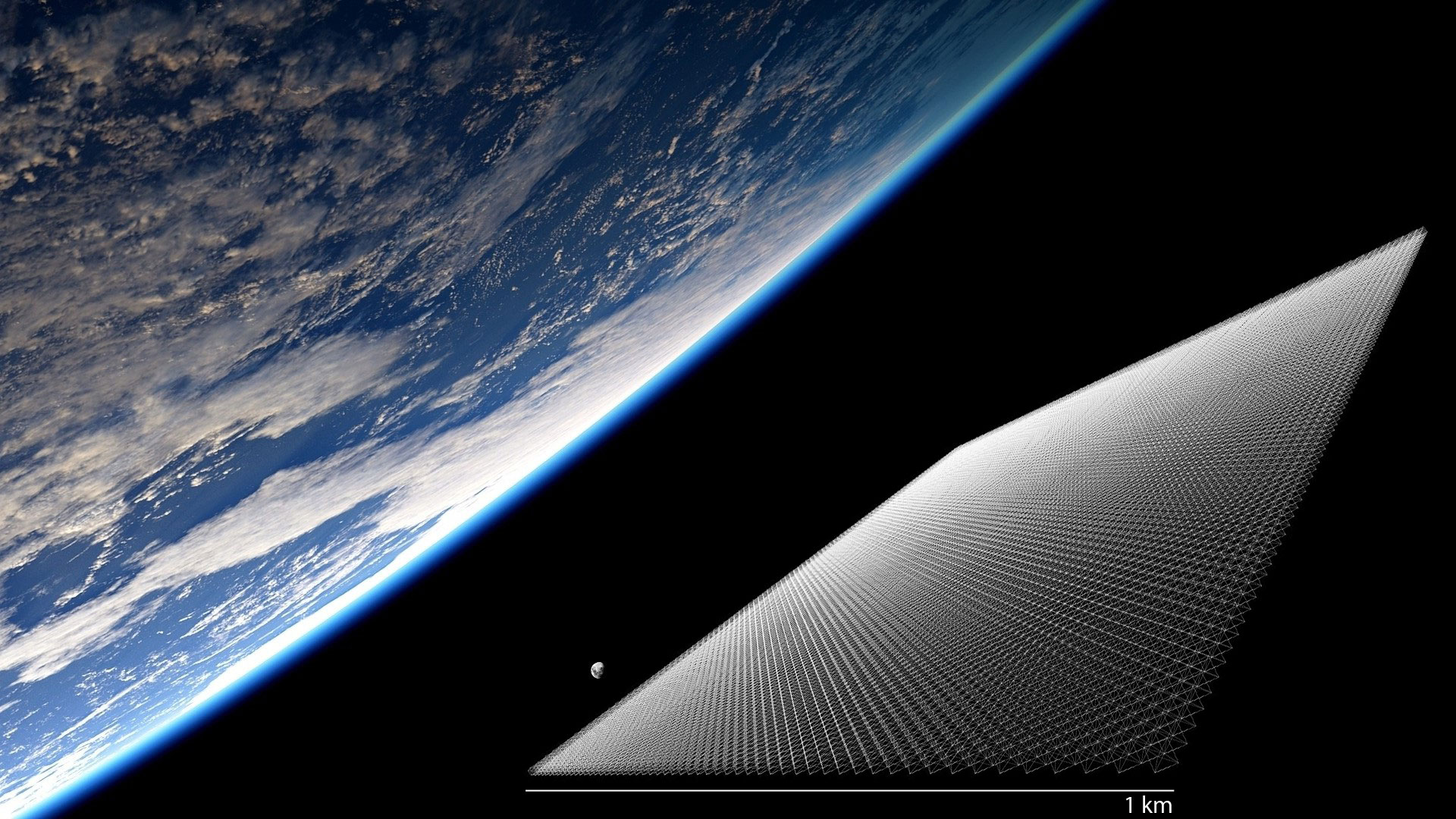

1km x 1km x 10m space truss

100 x 100 x 1 cells

100,000 struts @ 10m length

1,000,000m total length

TBD:

-packing volume

-build time

-structural requirements

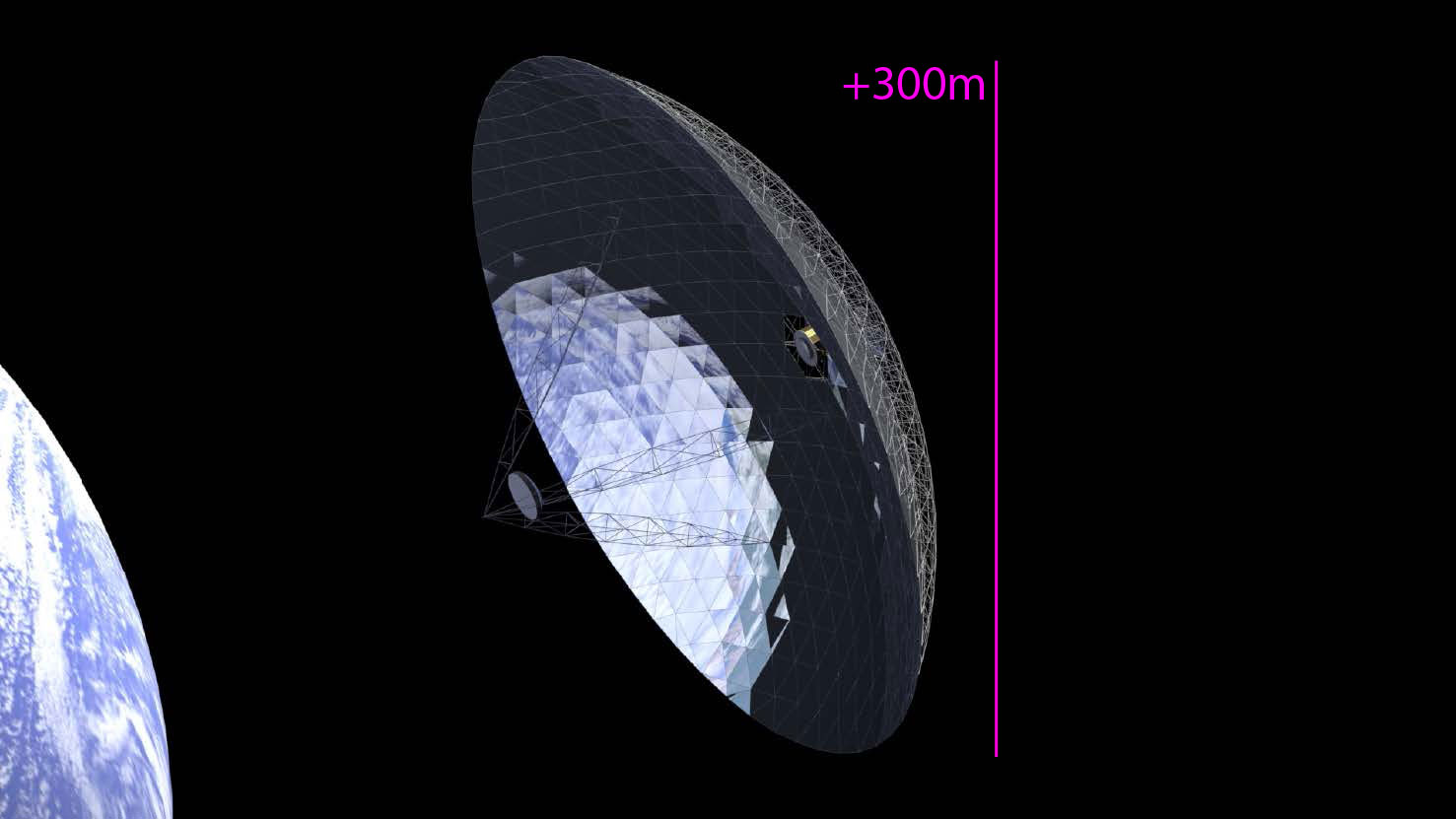

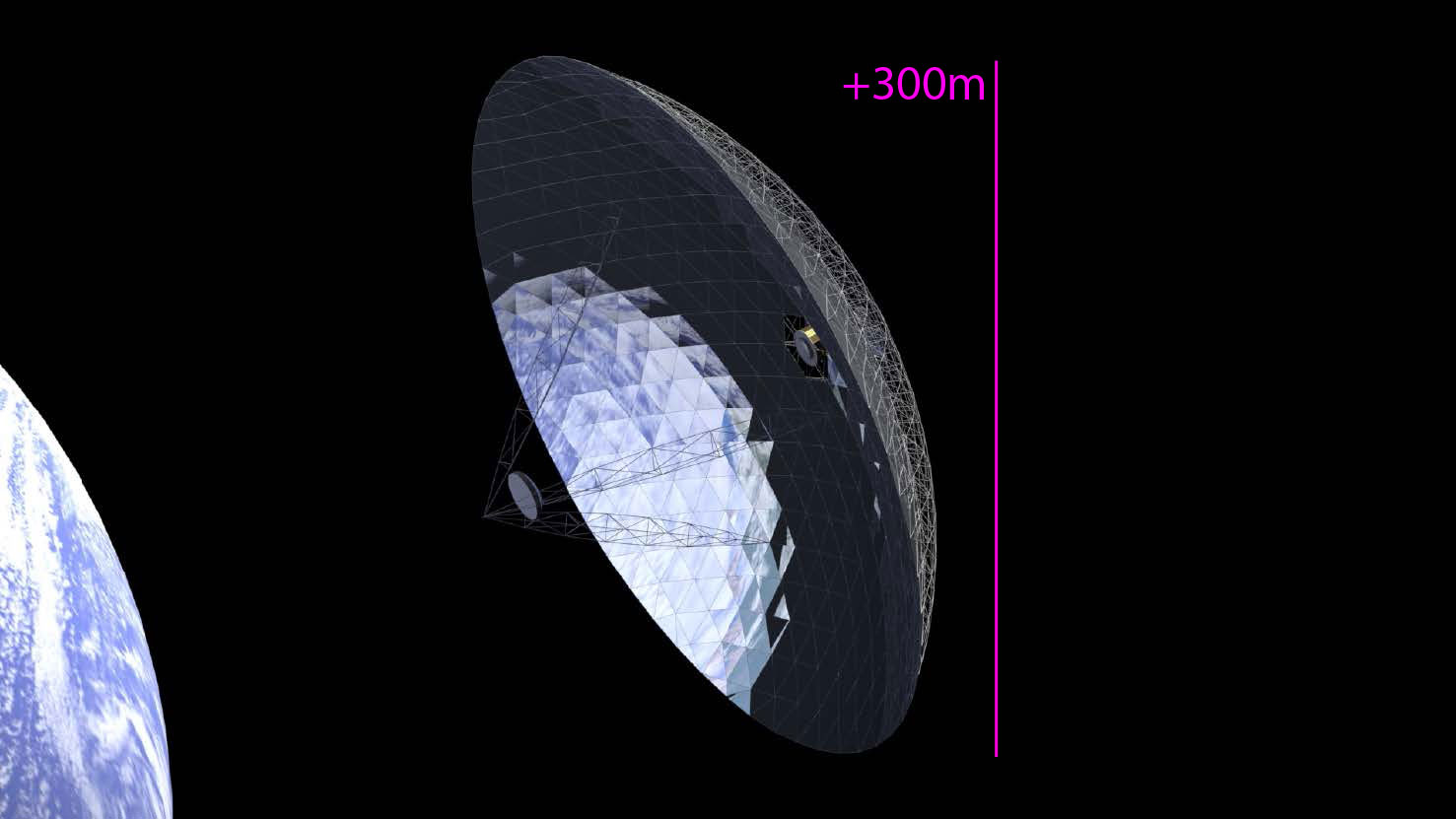

300m diameter dish "arecibo in orbit", source: www.tethers.com

applications:

-high bandwidth communications with Mars & deep space probes

-detection and characterization of NEOs

-solar thermal power

-space habitation

analysis

E = 1.35 x 10^6 psi / 9300 MPa

assuming n = 1 for pinned connections

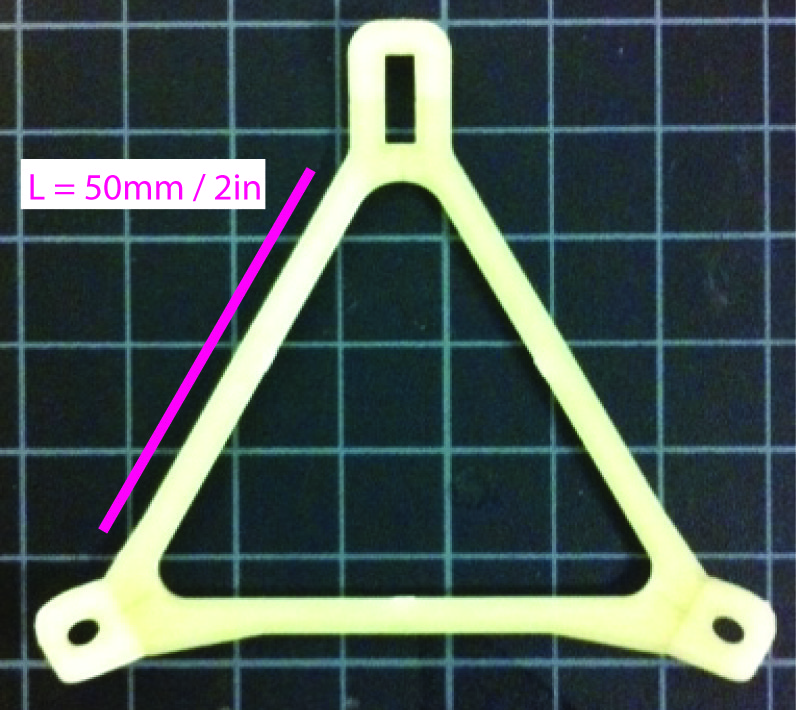

F = π2 (1.35x10^6 psi) (0.00005in^4) / (2in)^2 =

16.65 lb / 75 N

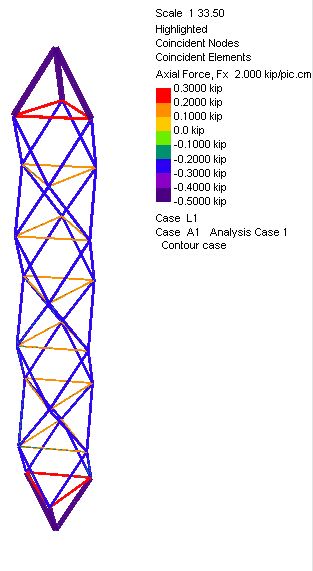

for 1P applied load, the struts take 0.2P in compression (ignoring boundary conditions)

if 0.2P = 16.65 lb, P = 83.25 lb

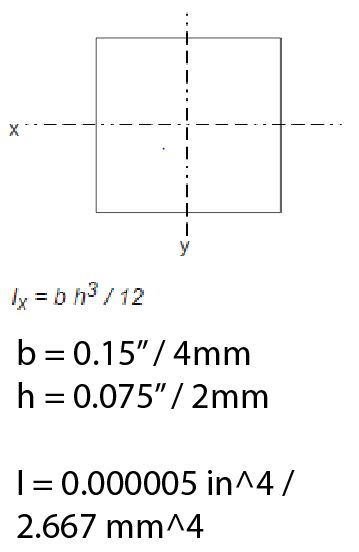

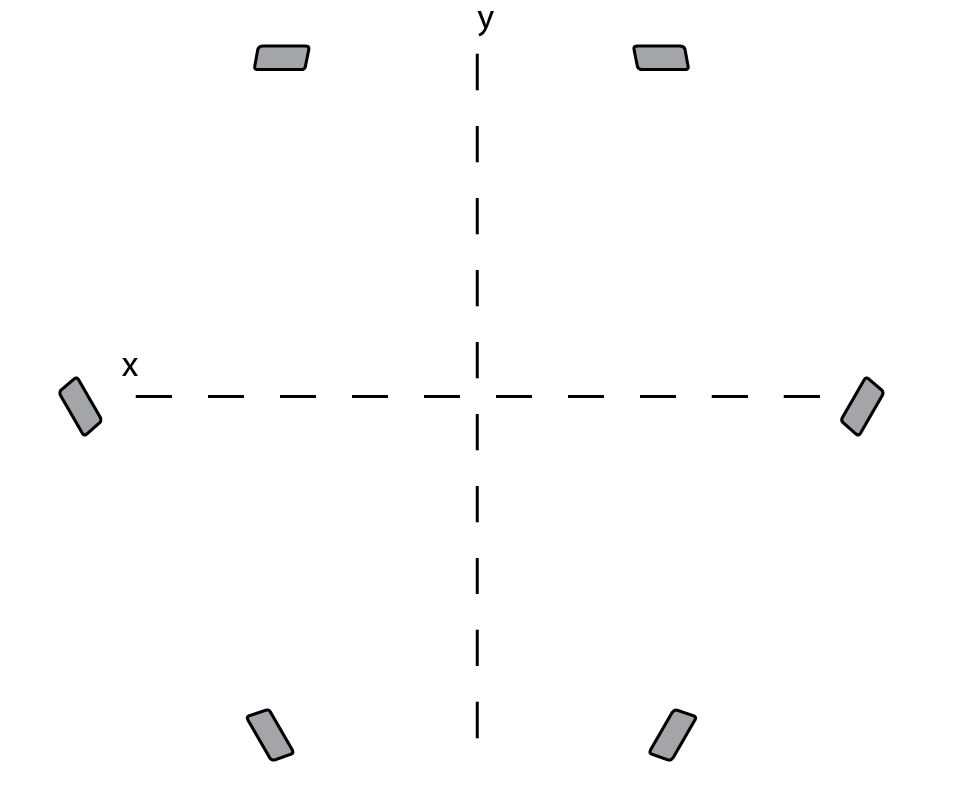

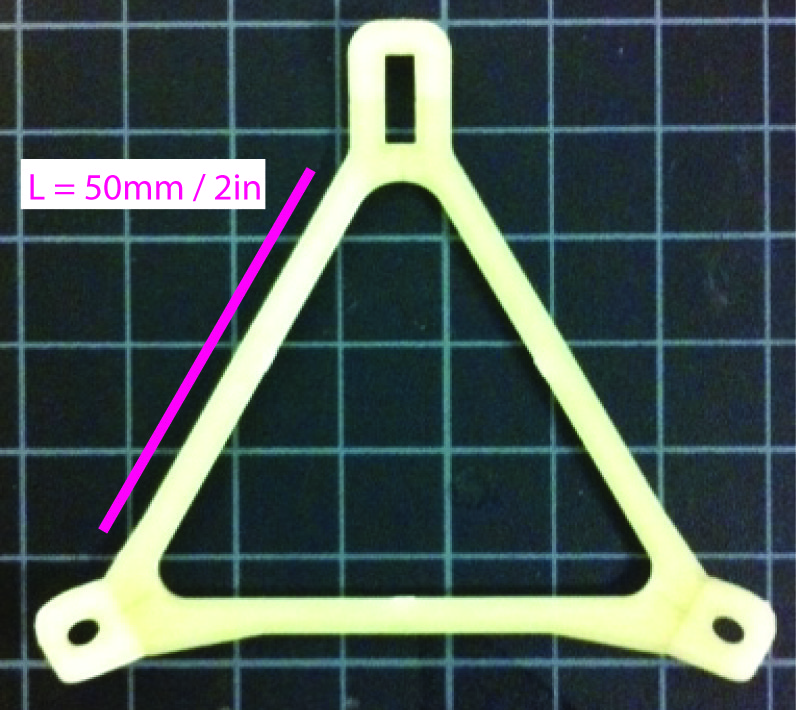

I of the column is determined by taking the cross section as shown:

Iy is found to be 0.092 in^4

Now we determine the global length that will result in buckling at P

L = (π2EI/P)^(1/2)

L = (π2(1.35 x 10^6 psi)(0.092in^4) / 83.25 lb)^(1/2)

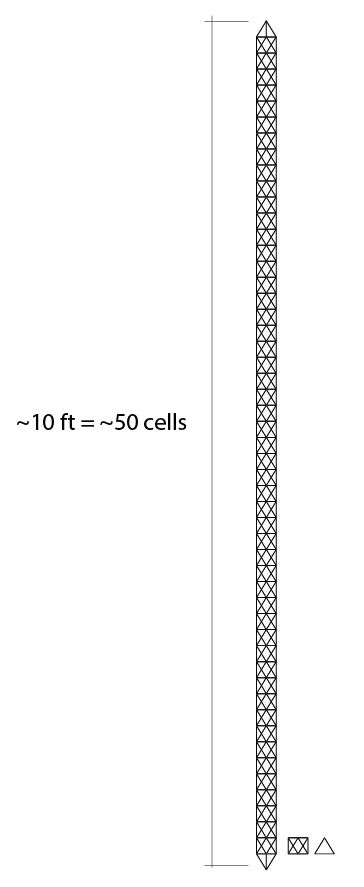

L = 121 in or 10.11 ft

So for the given design, a ~10' (~50 cell) column will fail at a load of 83 lbs, and the struts will fail with their corresponding load of 16 lbs

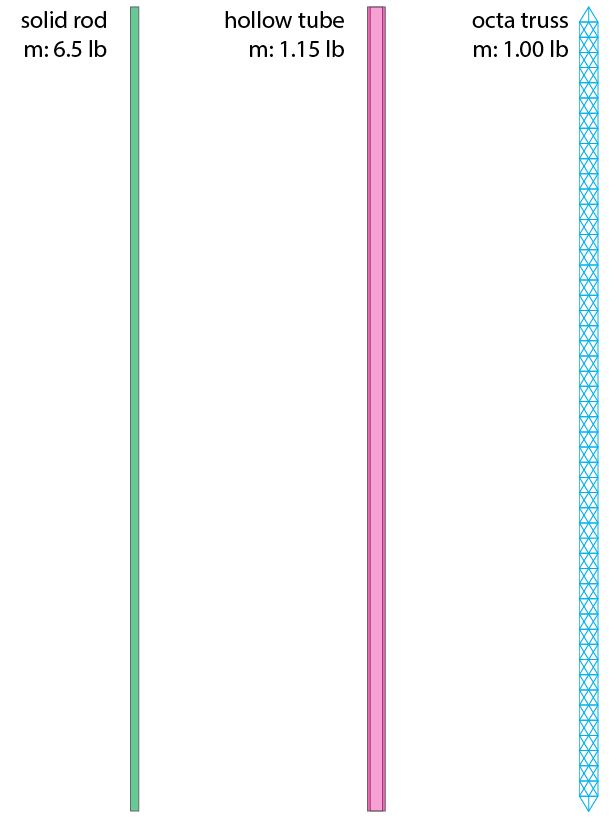

zytel density = 1.39 g/cm3 = 0.05 lb/in3

1 part = 0.1335 in3 = 0.006675 lb

1 cell = 3 parts = 0.02 lb

50 cell column = 1 lb

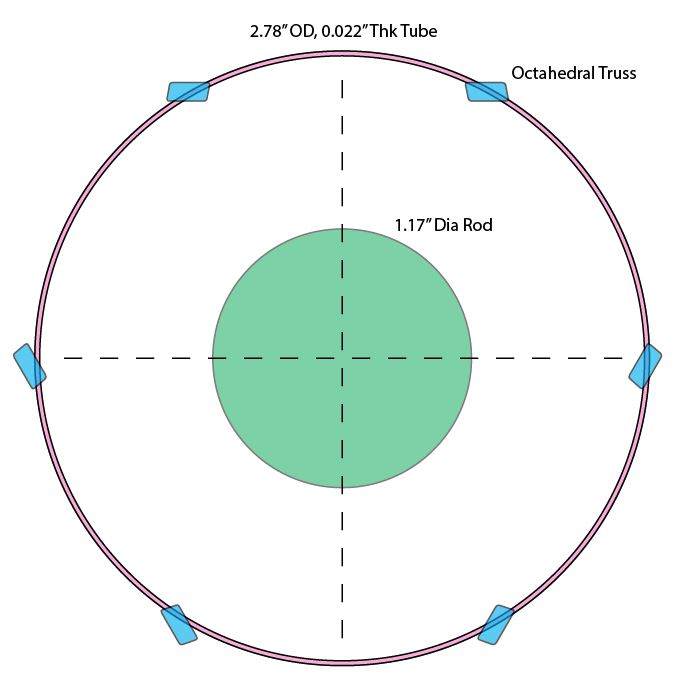

comparison with different cross sections with same I:

truss wins for mass!

BUT

improvement can be made by replacing the solid struts of the part with tubes. this increasing buckling capacity and potentially reduces mass

(the manufacturing challenges will be considered at a later time)

QUICK MASS/VOLUME CALC FOR LAUNCH SHROUD

MASS

1lb/10ft= .15 kg/m

10^6m = 1.5 * 10^5 kg

Ariane 5 launch shroud:

LEO: @21,000 kg = x7 launch shrouds

GTO: @10,500 kg = x14 launch shrouds

VOLUME

150 parts/10ft = 50 parts / m

1,000,000m = 50,000,000 parts

Ariane 5 launch shroud:

7.7m x 4.5m x 4.5m = 155 m3

= 20,000,000 parts

= x2.5 launch shrouds ----> MASS LIMITED!

current hierarchical prototype

1km x 1km x 10m space truss

100 x 100 x 1 cells

100,000 struts @ 10m length

1,000,000m total length

TBD:

-packing volume

-build time

-structural requirements

300m diameter dish "arecibo in orbit", source: www.tethers.com

applications:

-high bandwidth communications with Mars & deep space probes

-detection and characterization of NEOs

-solar thermal power

-space habitation

analysis

-the standard procedure for

minimum-mass, high strength slender structures is to equate

global and local buckling modes

-NOTE: this is a linear elastic analysis. non linear behavior will likely worsen performance, and will be investigated soon.

-local buckling of injection molded parts:

-NOTE: this is a linear elastic analysis. non linear behavior will likely worsen performance, and will be investigated soon.

-local buckling of injection molded parts:

F = n π2 E

I / L2

(1)

E = 1.35 x 10^6 psi / 9300 MPa

assuming n = 1 for pinned connections

F = π2 (1.35x10^6 psi) (0.00005in^4) / (2in)^2 =

16.65 lb / 75 N

for 1P applied load, the struts take 0.2P in compression (ignoring boundary conditions)

if 0.2P = 16.65 lb, P = 83.25 lb

I of the column is determined by taking the cross section as shown:

Iy is found to be 0.092 in^4

Now we determine the global length that will result in buckling at P

L = (π2EI/P)^(1/2)

L = (π2(1.35 x 10^6 psi)(0.092in^4) / 83.25 lb)^(1/2)

L = 121 in or 10.11 ft

So for the given design, a ~10' (~50 cell) column will fail at a load of 83 lbs, and the struts will fail with their corresponding load of 16 lbs

zytel density = 1.39 g/cm3 = 0.05 lb/in3

1 part = 0.1335 in3 = 0.006675 lb

1 cell = 3 parts = 0.02 lb

50 cell column = 1 lb

comparison with different cross sections with same I:

truss wins for mass!

BUT

improvement can be made by replacing the solid struts of the part with tubes. this increasing buckling capacity and potentially reduces mass

(the manufacturing challenges will be considered at a later time)

QUICK MASS/VOLUME CALC FOR LAUNCH SHROUD

MASS

1lb/10ft= .15 kg/m

10^6m = 1.5 * 10^5 kg

Ariane 5 launch shroud:

LEO: @21,000 kg = x7 launch shrouds

GTO: @10,500 kg = x14 launch shrouds

VOLUME

150 parts/10ft = 50 parts / m

1,000,000m = 50,000,000 parts

Ariane 5 launch shroud:

7.7m x 4.5m x 4.5m = 155 m3

= 20,000,000 parts

= x2.5 launch shrouds ----> MASS LIMITED!