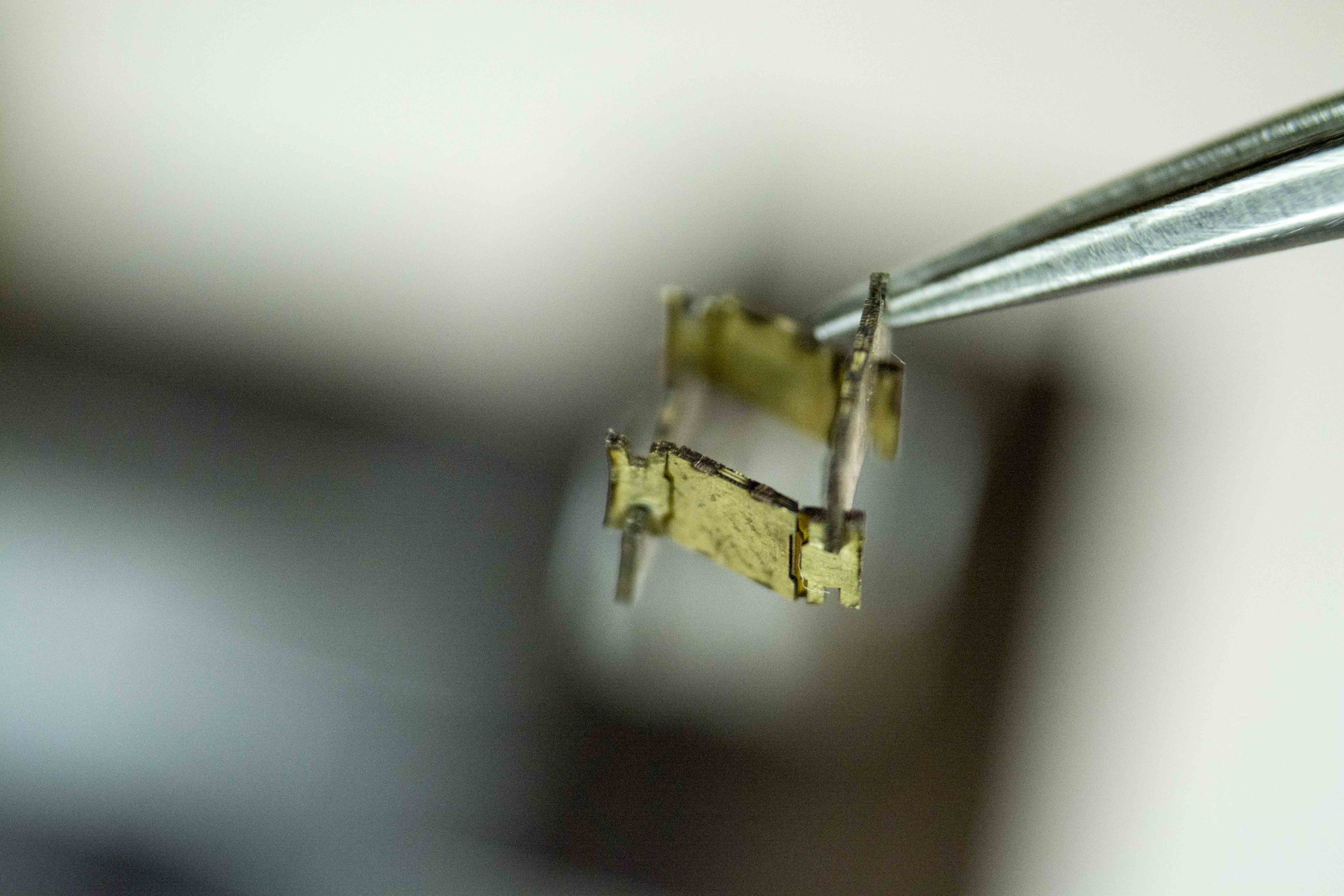

Hinge GIK

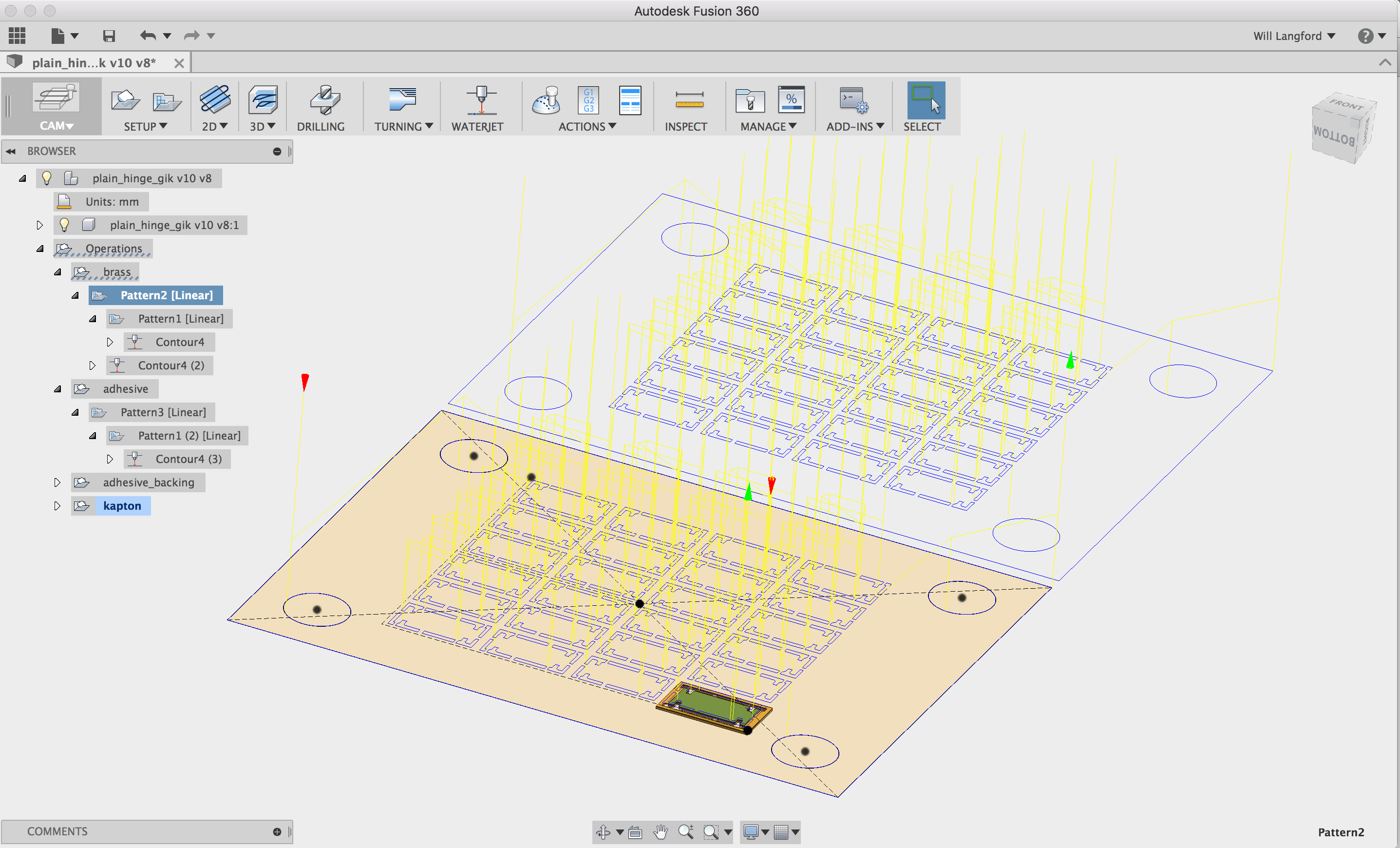

Toolpathing is done within Fusion360 using a custom post-processor to export GCode for the Oxford Laser.

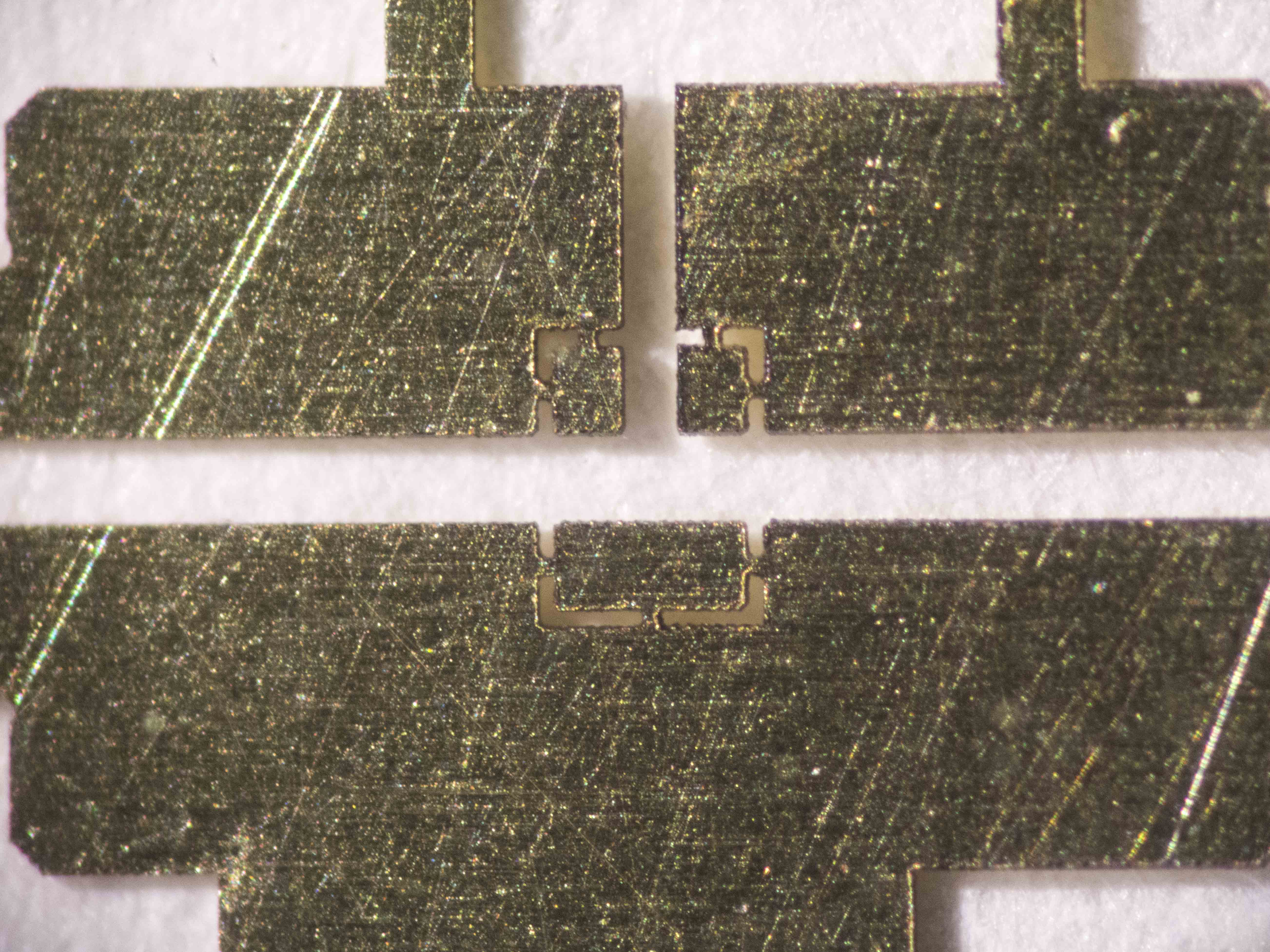

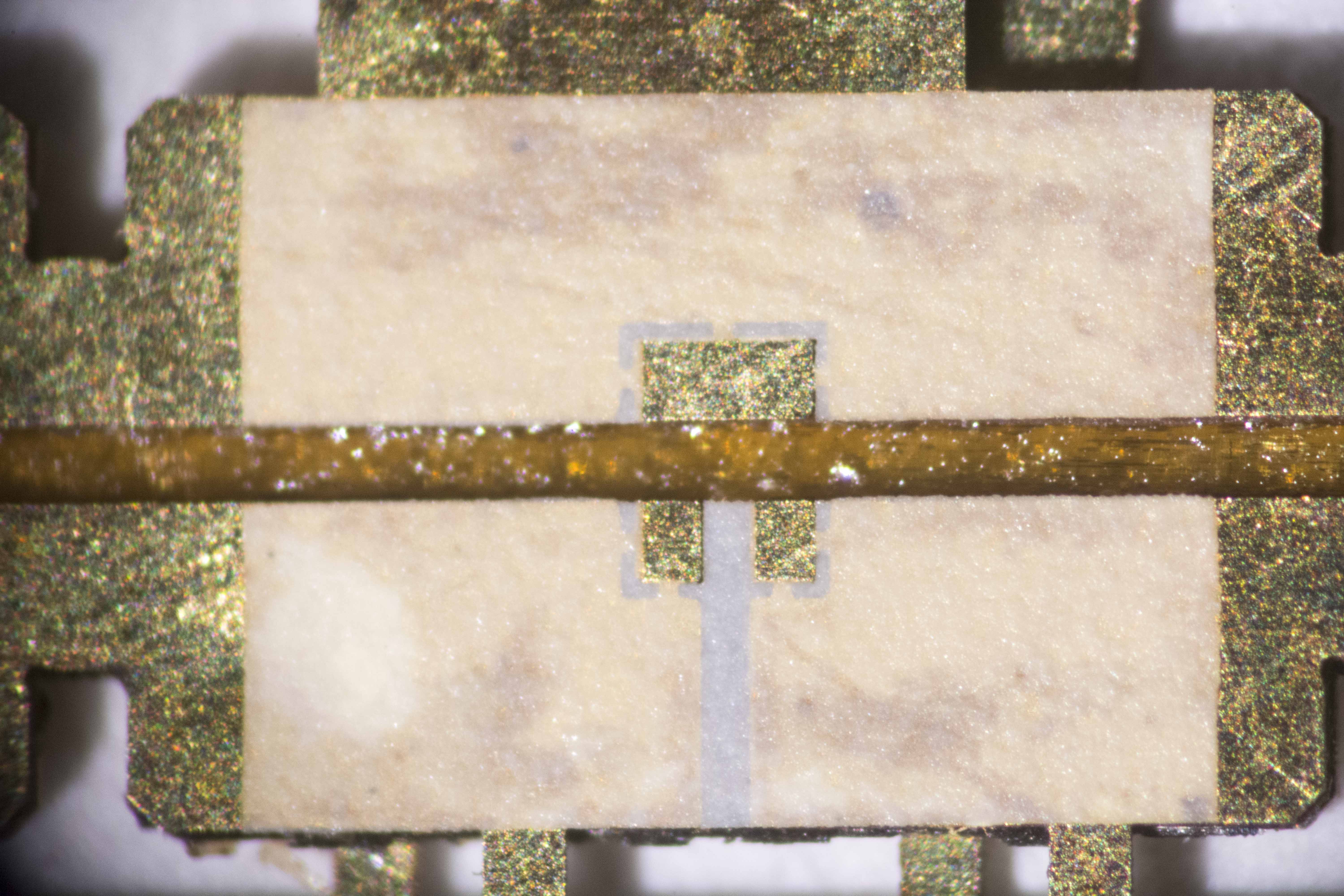

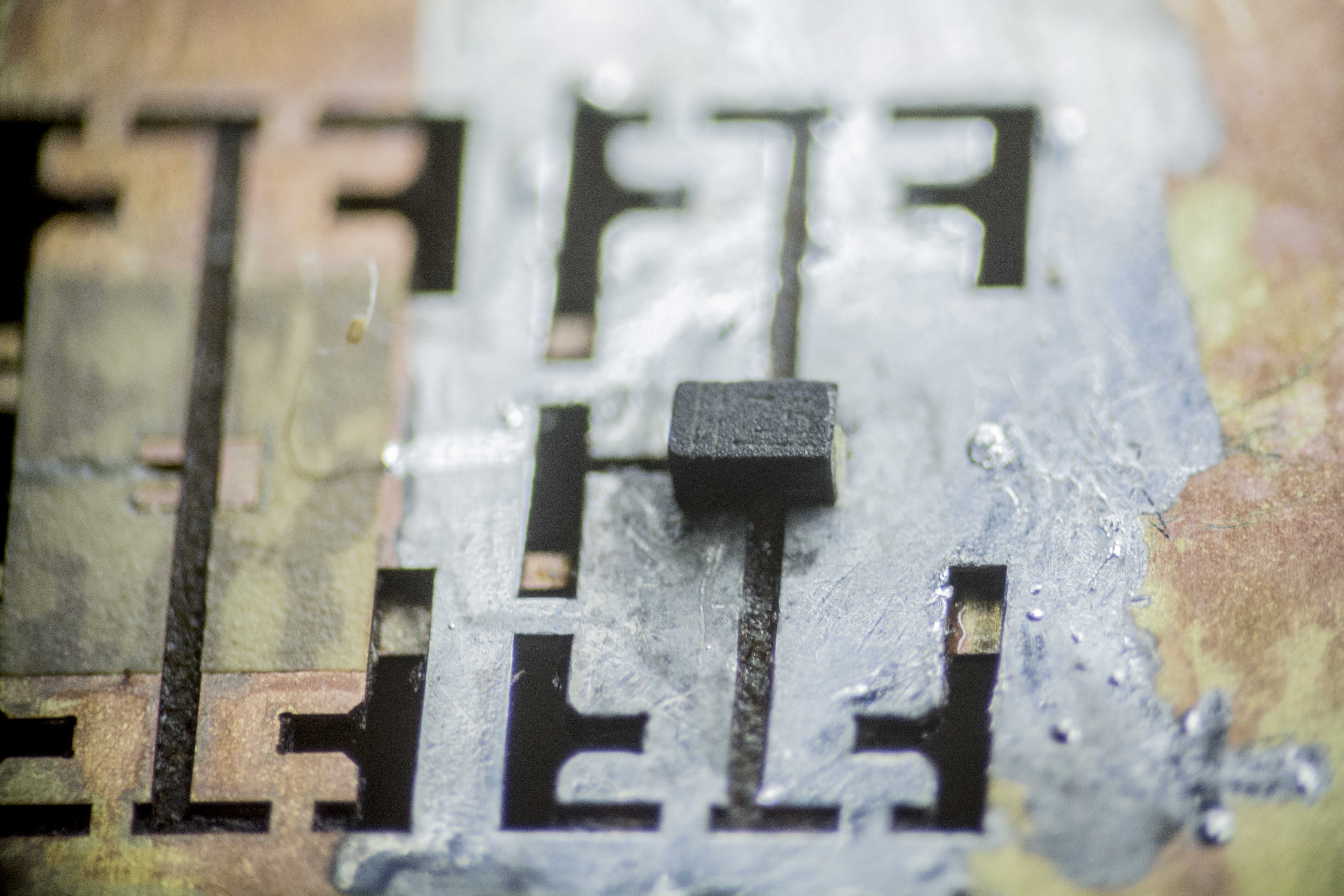

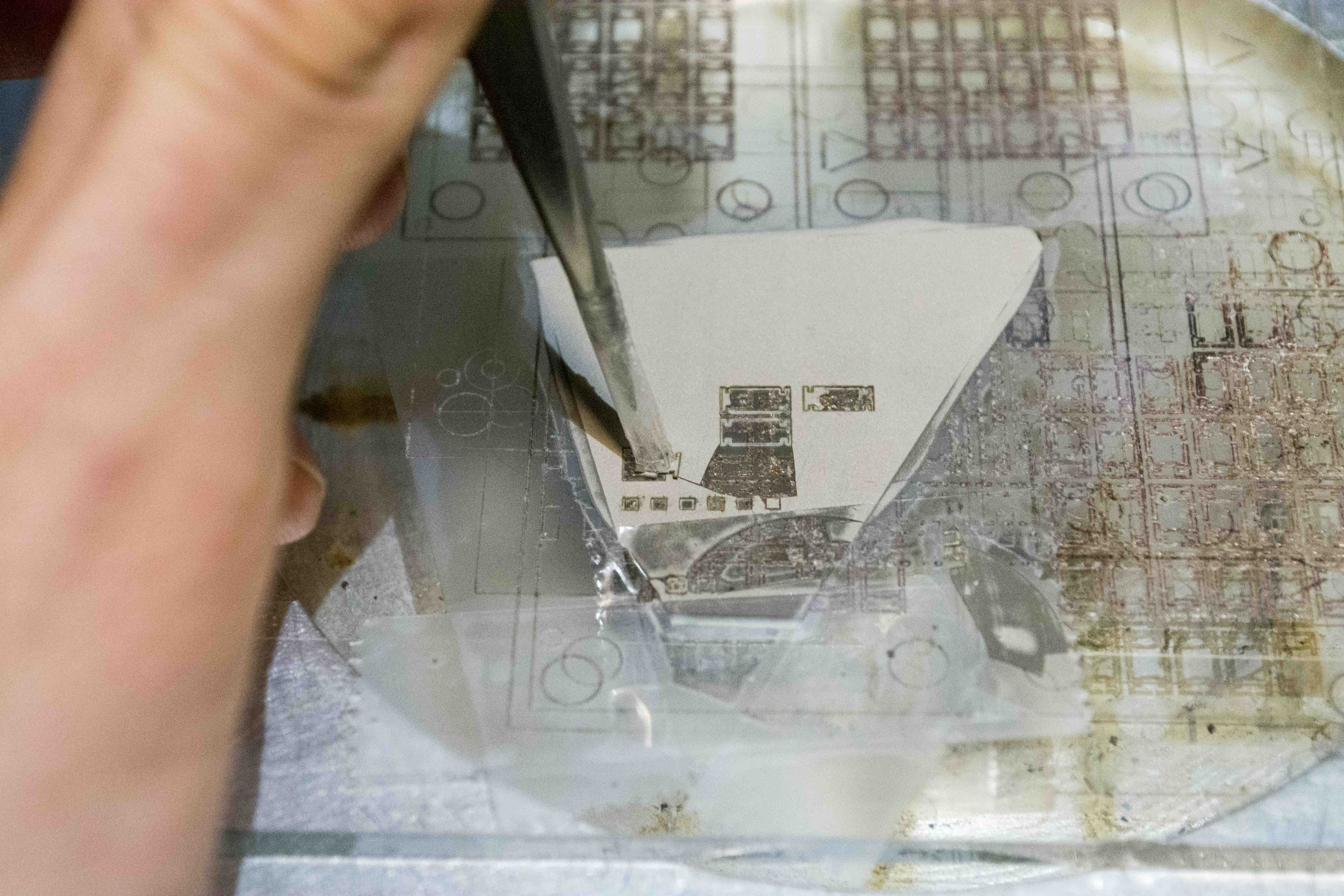

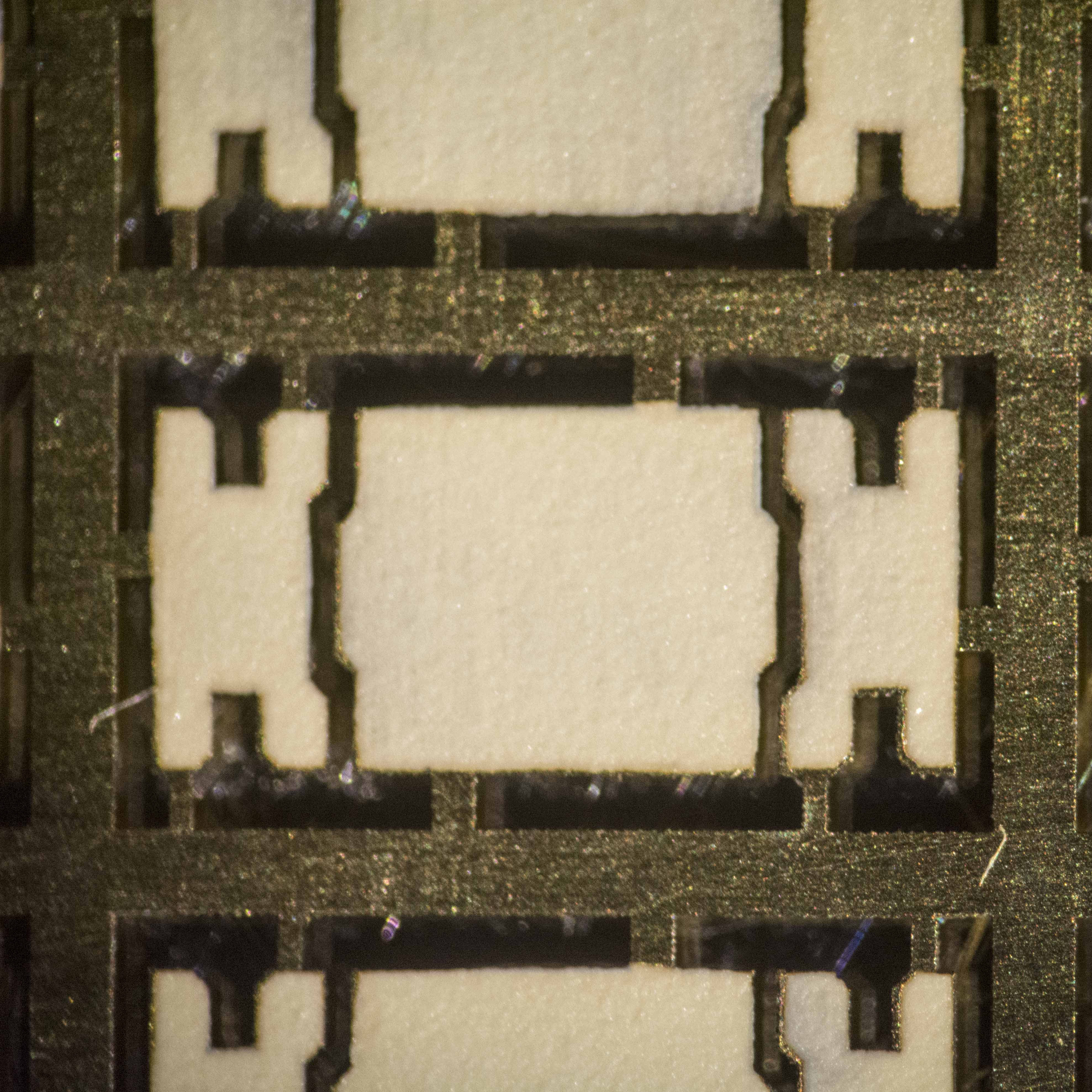

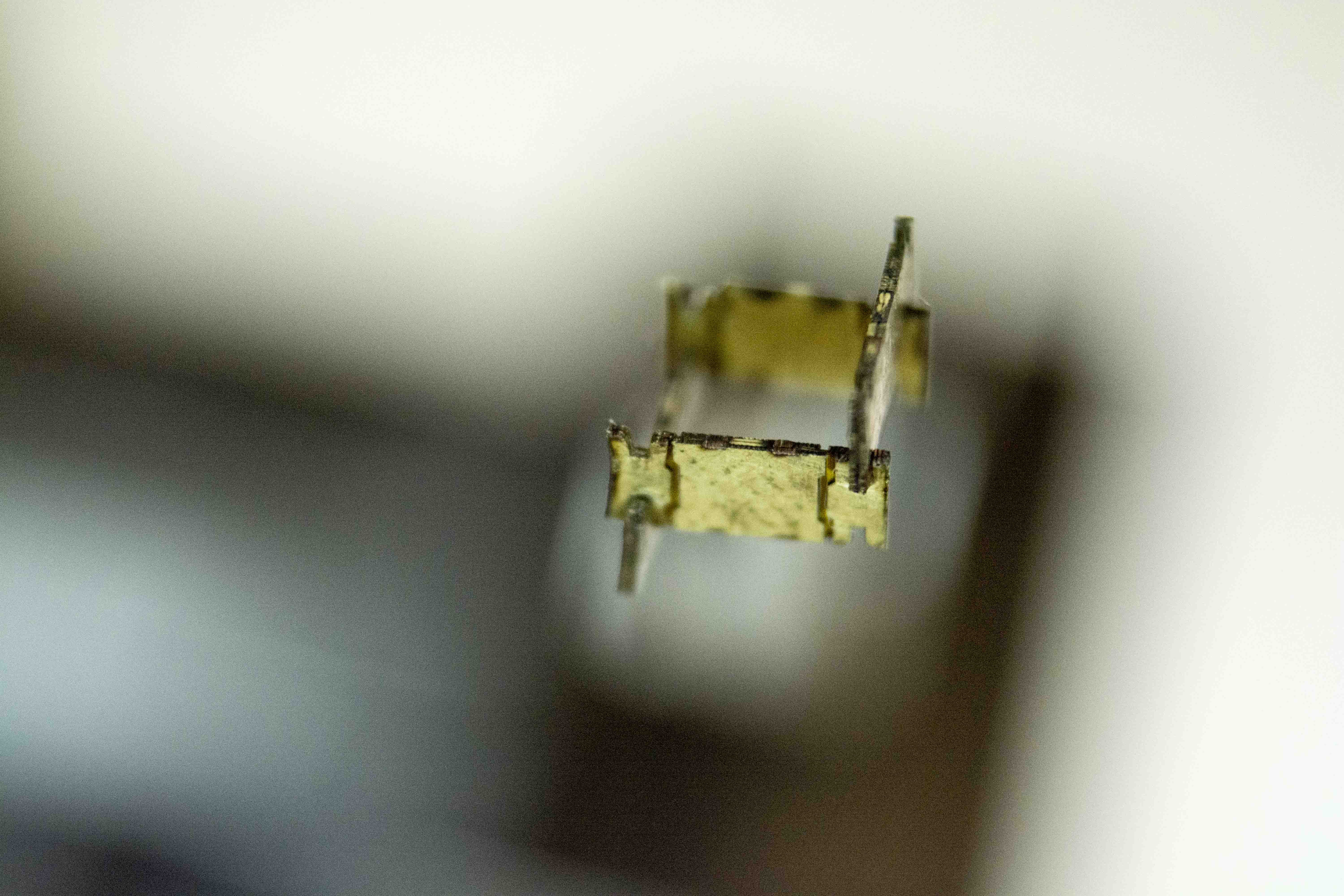

The pre-tacked adhesive layer is well aligned with the brass layers.

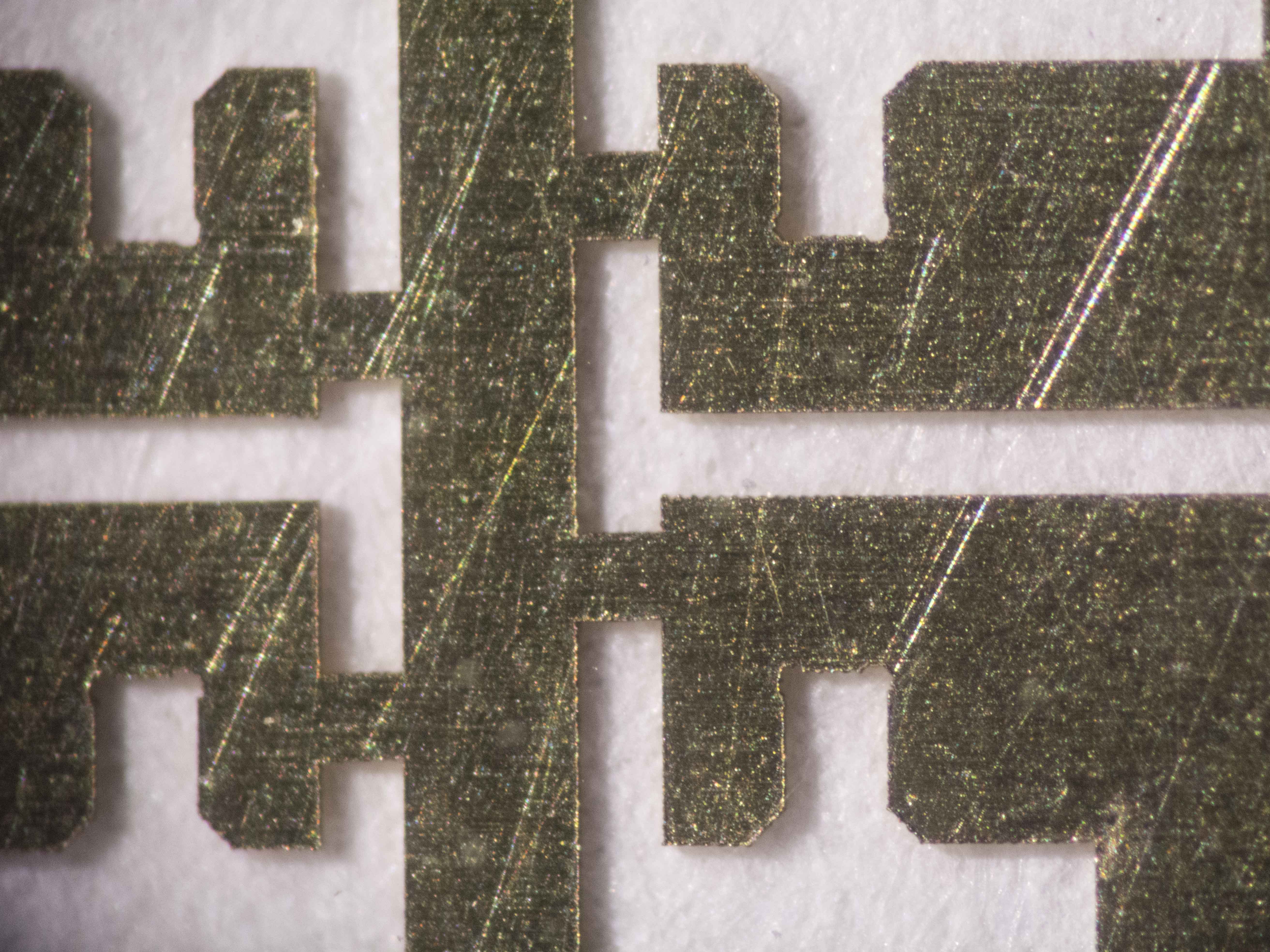

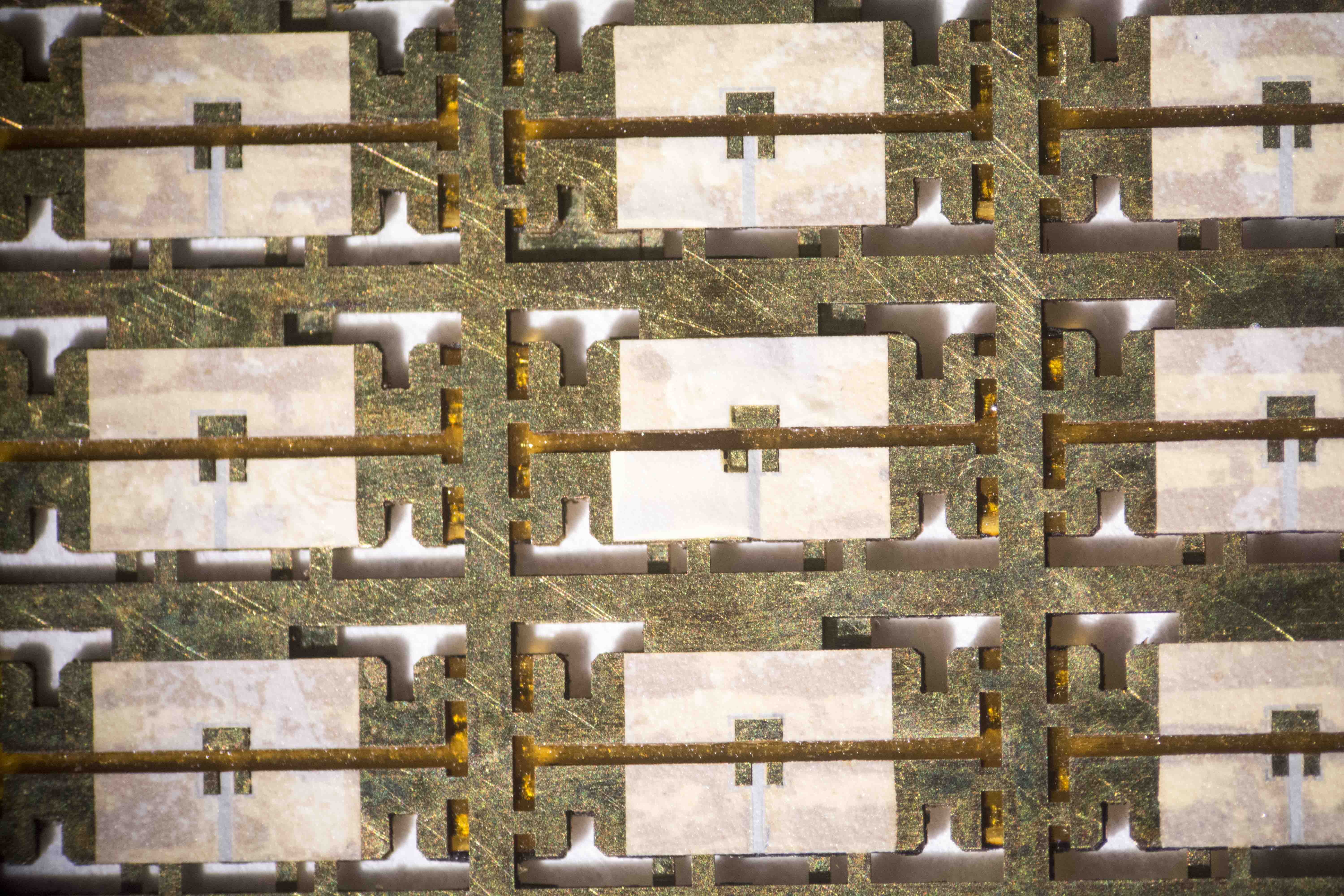

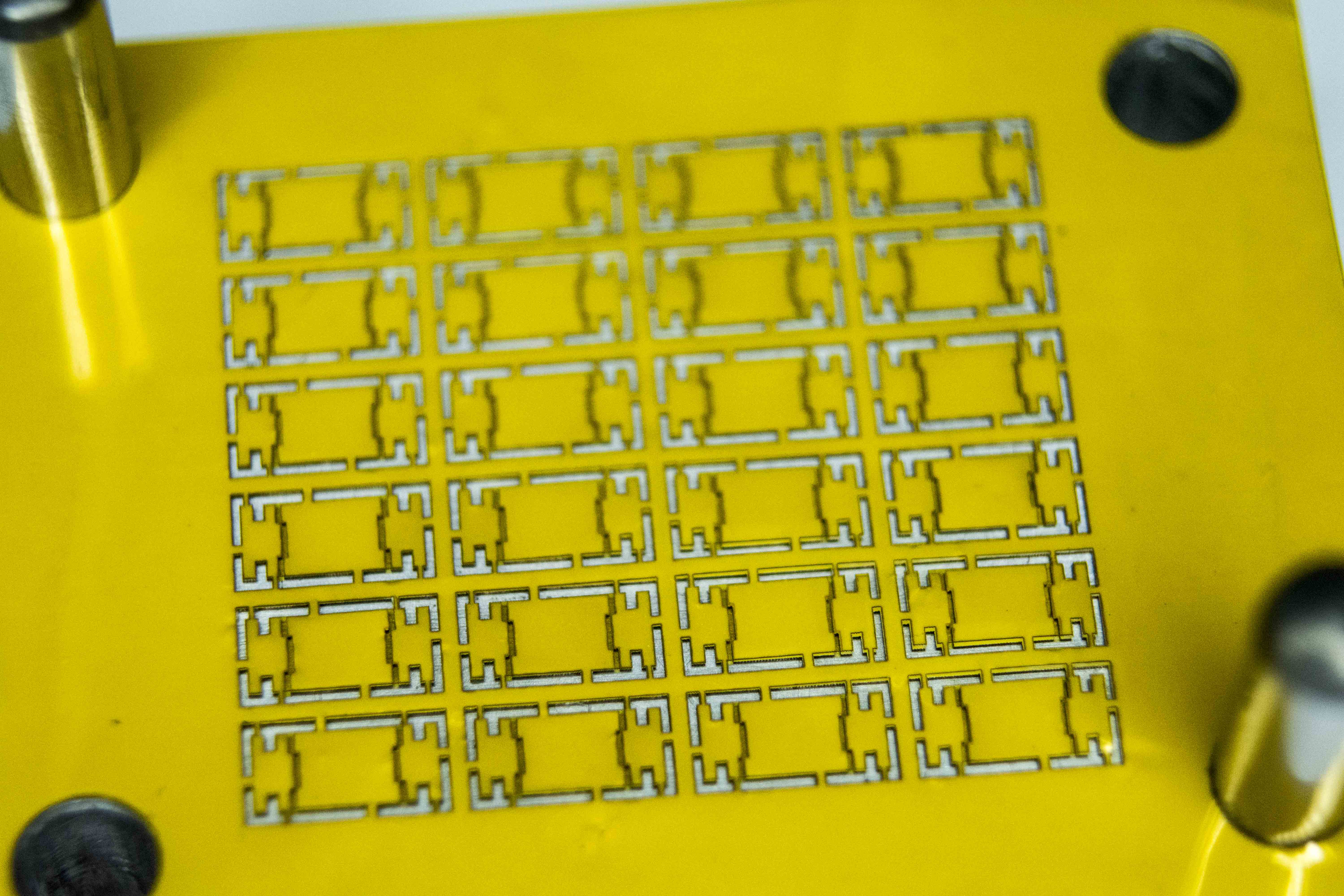

24 parts are made at once using the current heat-bonding fixture.

The heat-bonding step takes approximately 1 hour while cutting takes approximatley 3 hours (2hrs of which is for the brass layers).

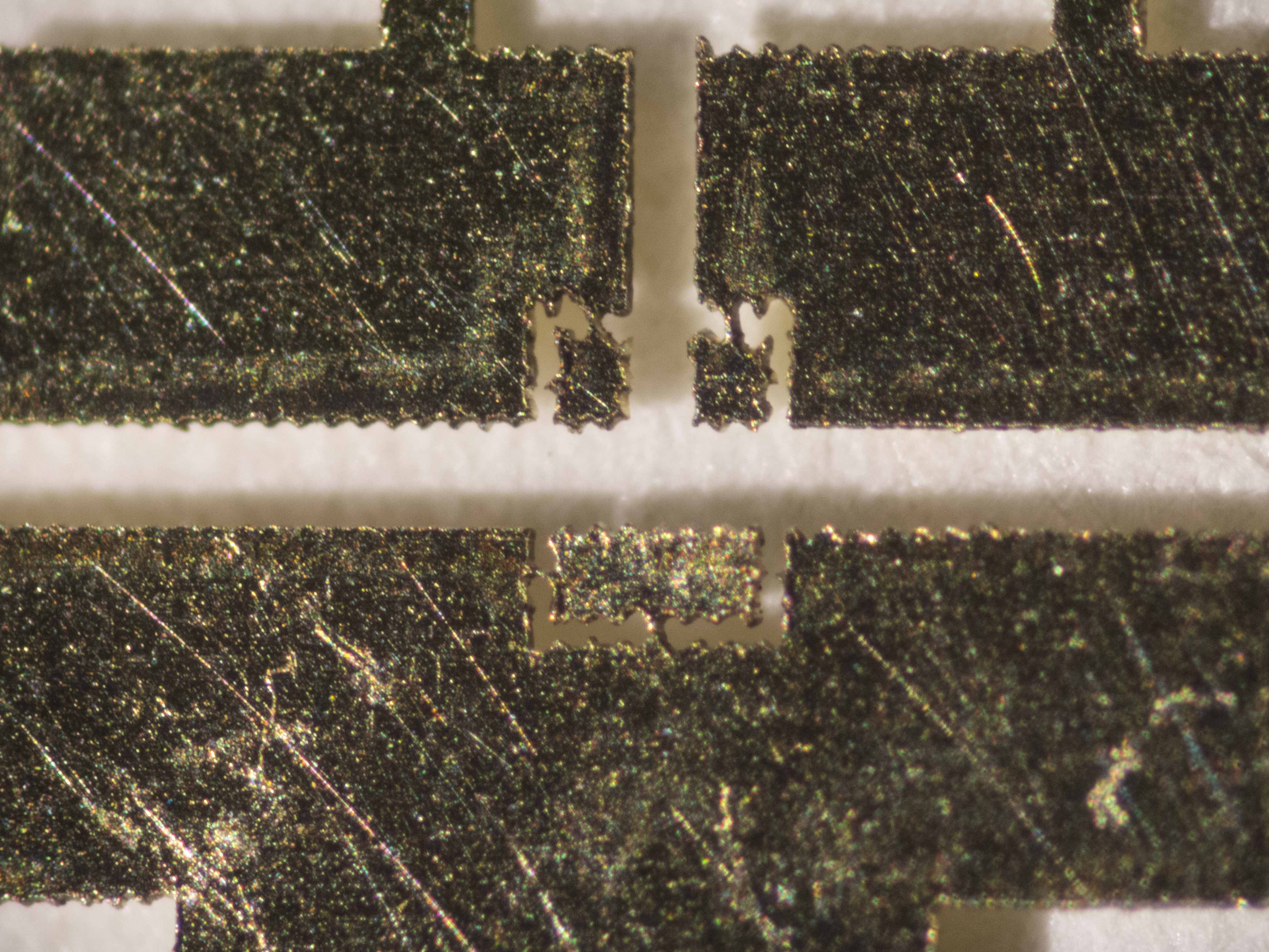

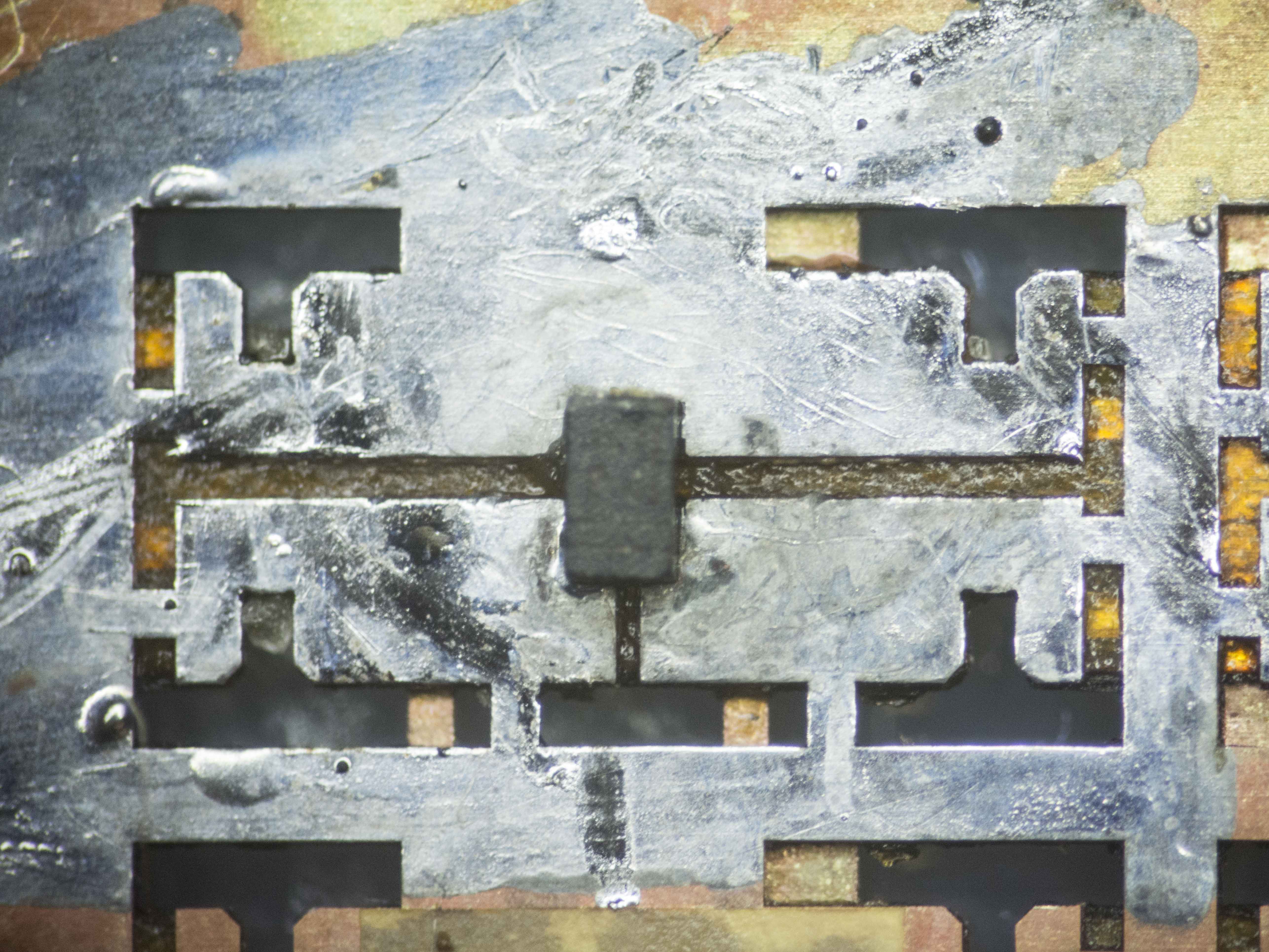

An interesting blue oxide formed on one of the batches. I believe this was caused by the remnants of a citric acid based spray adhesive remover.

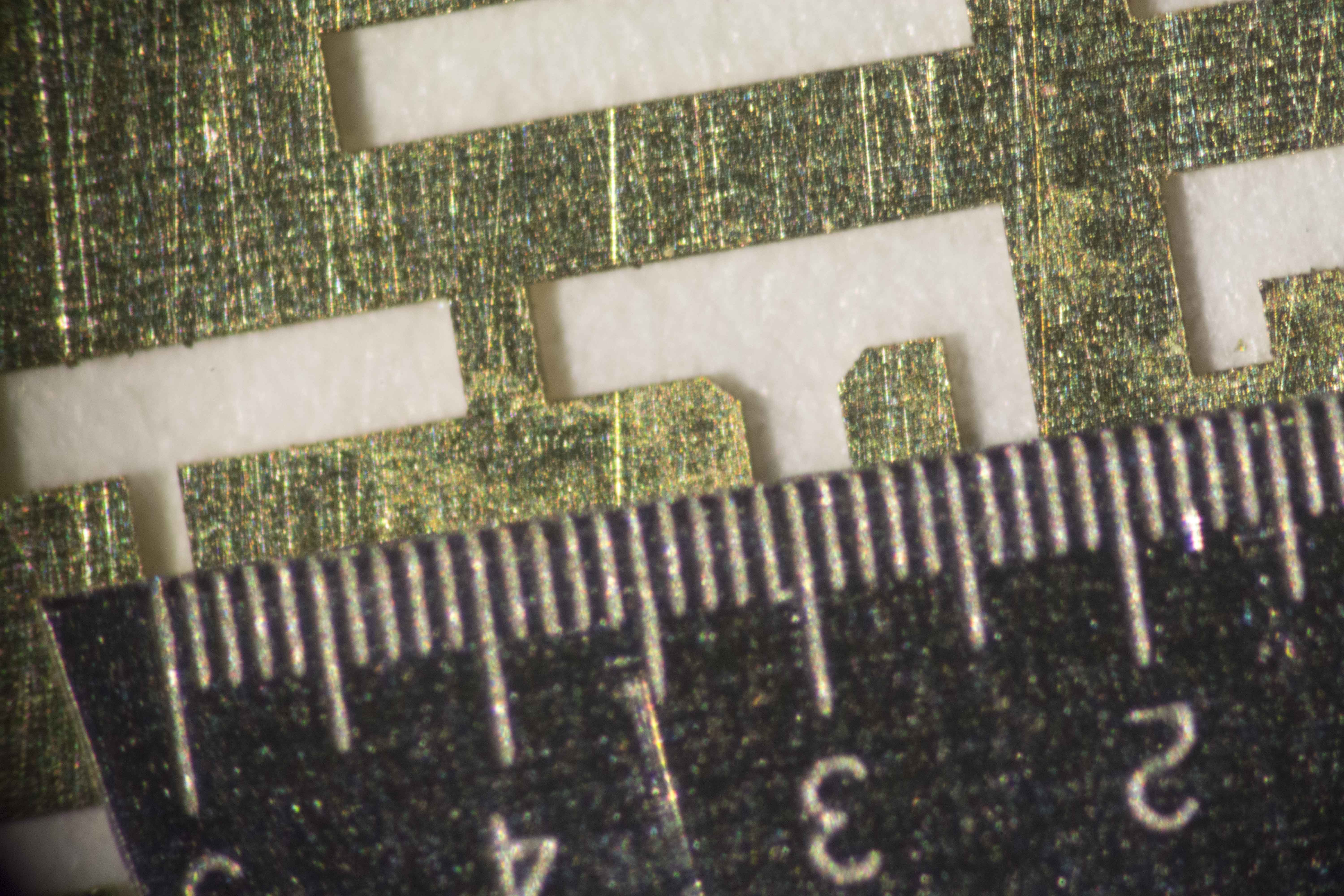

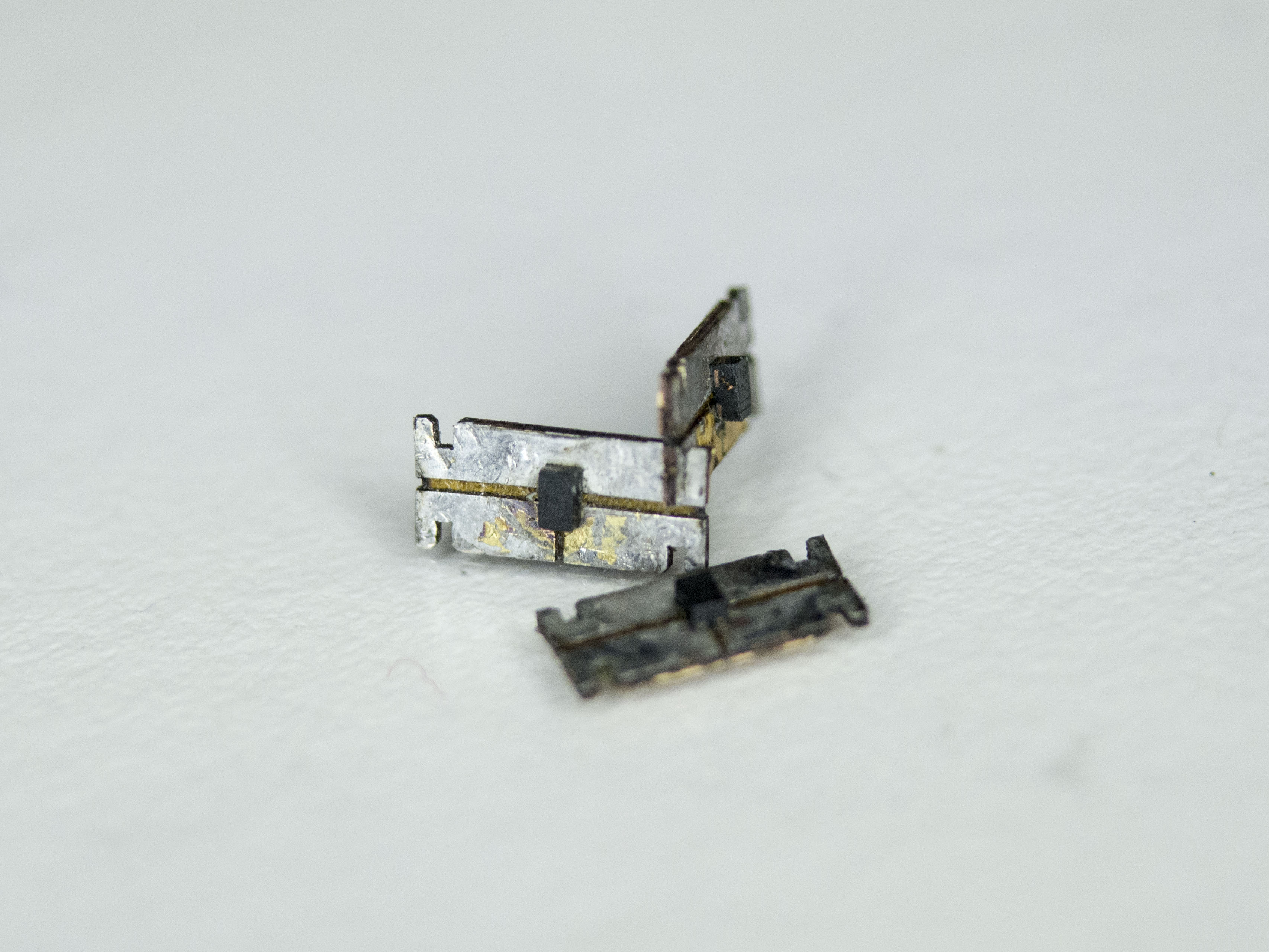

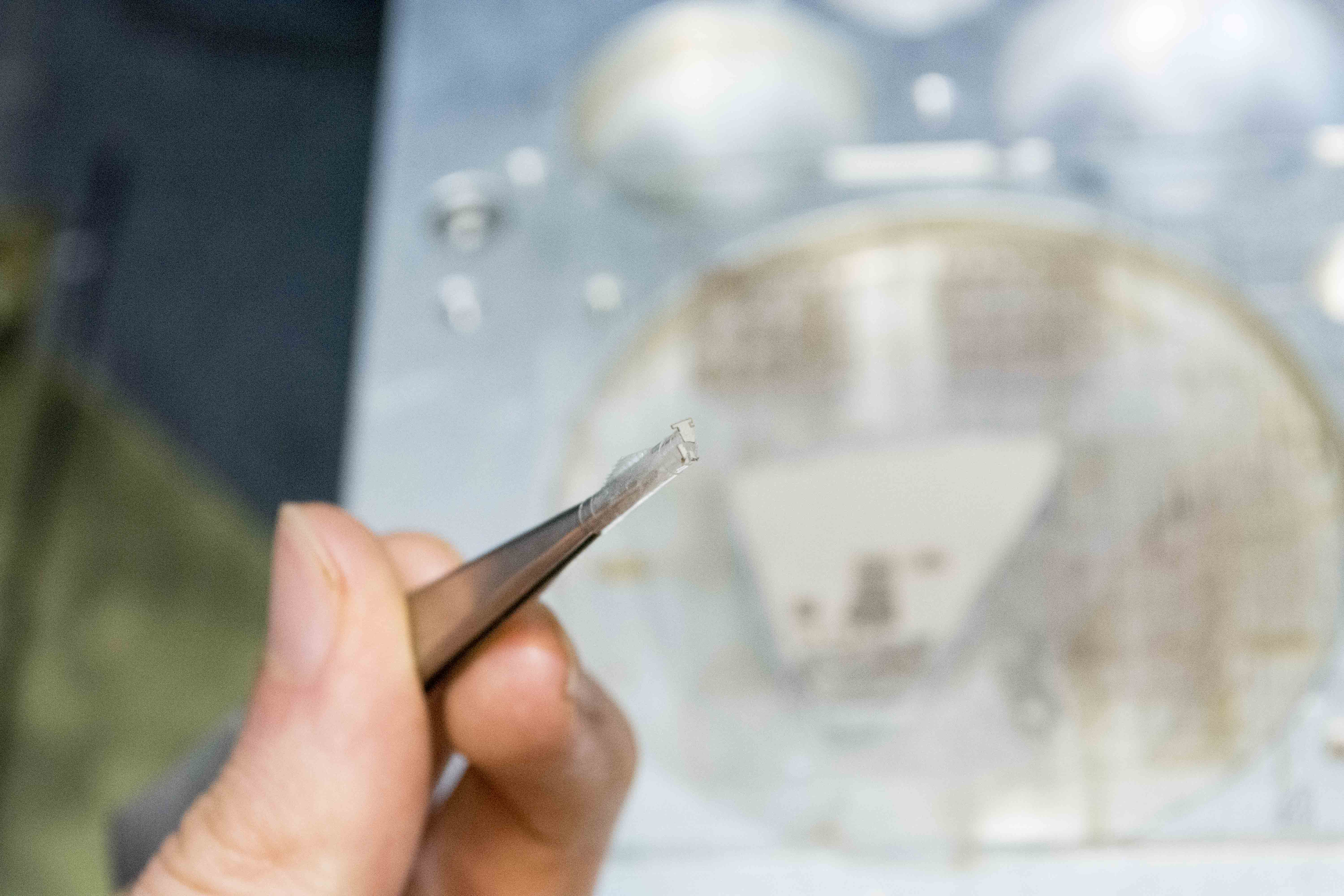

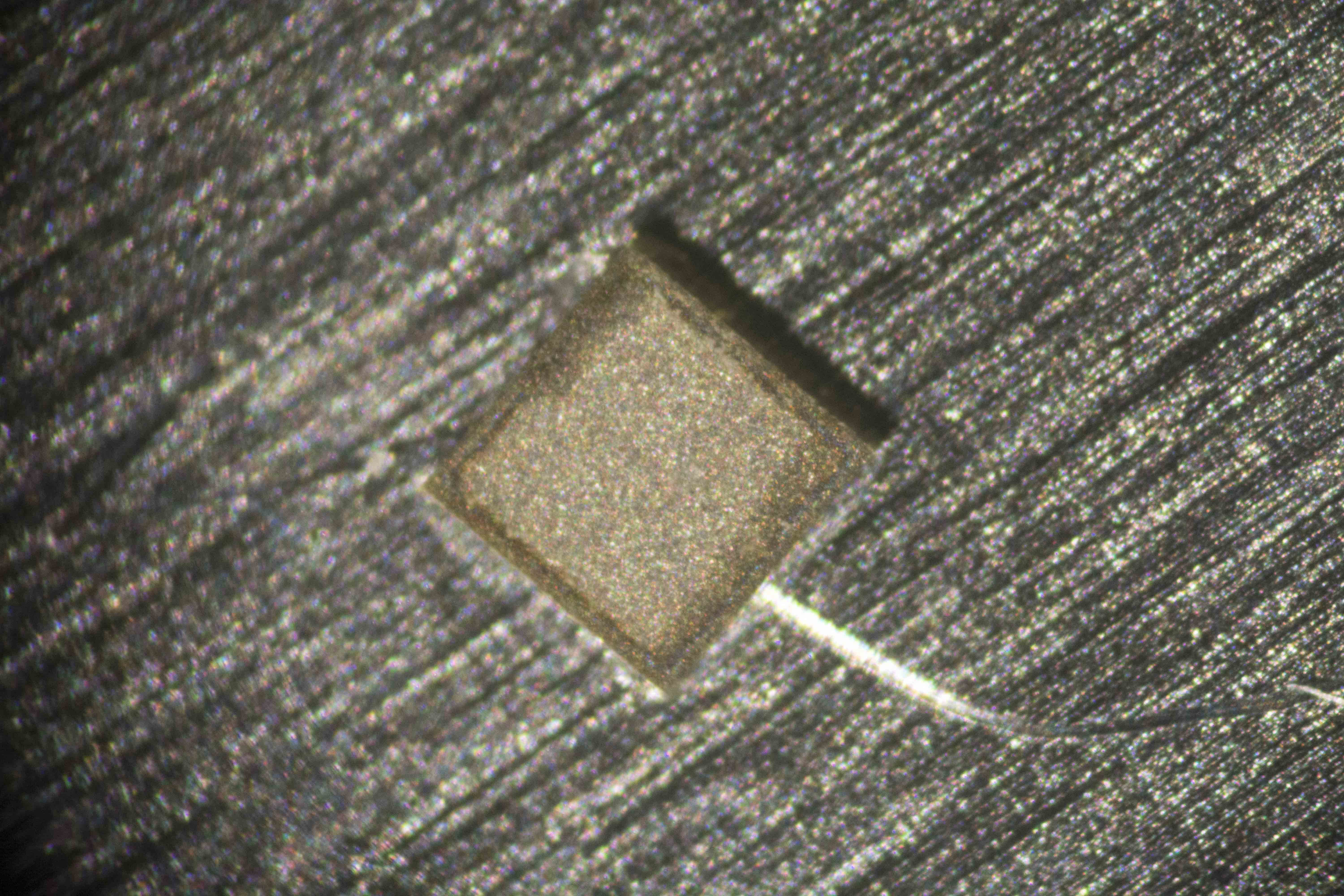

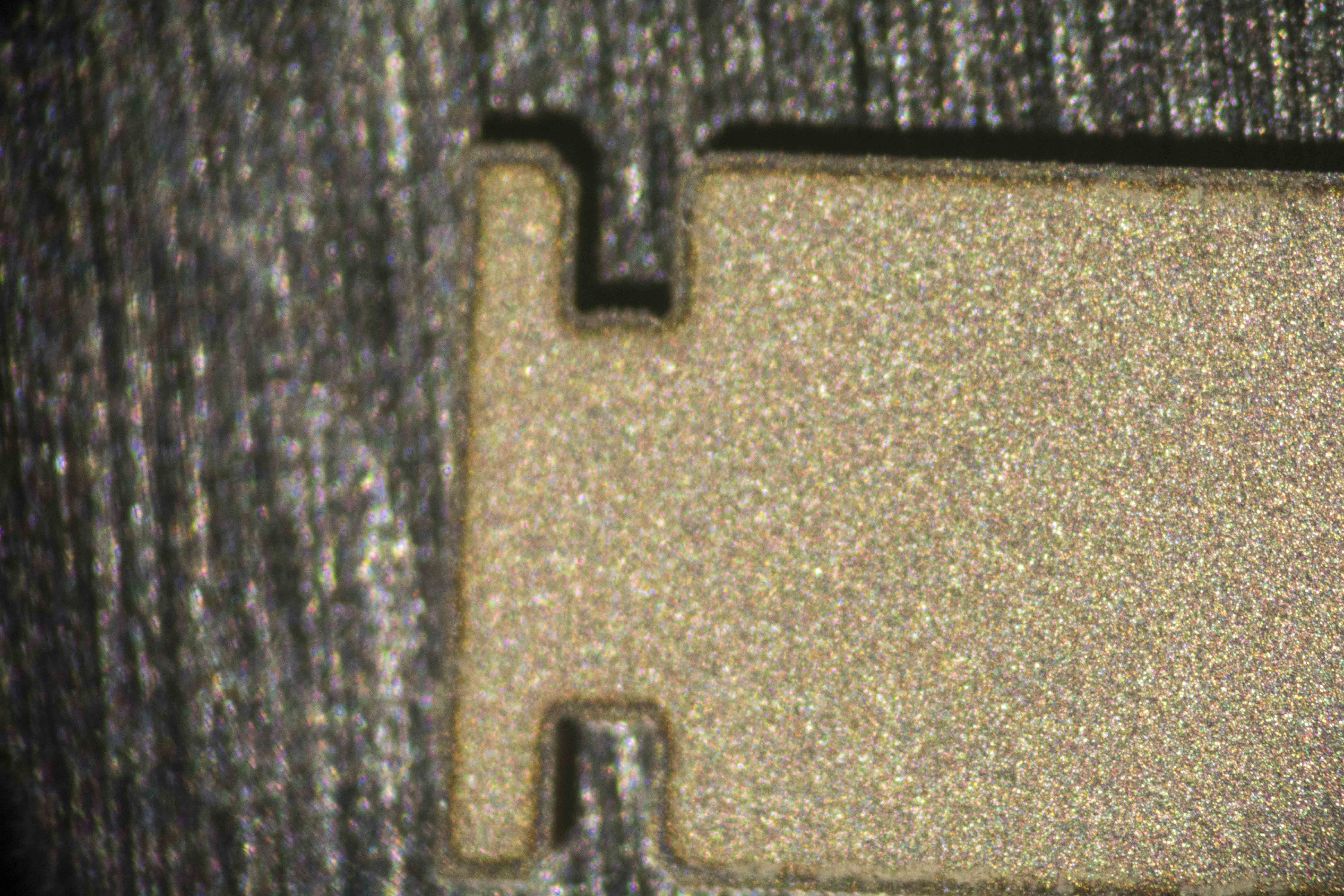

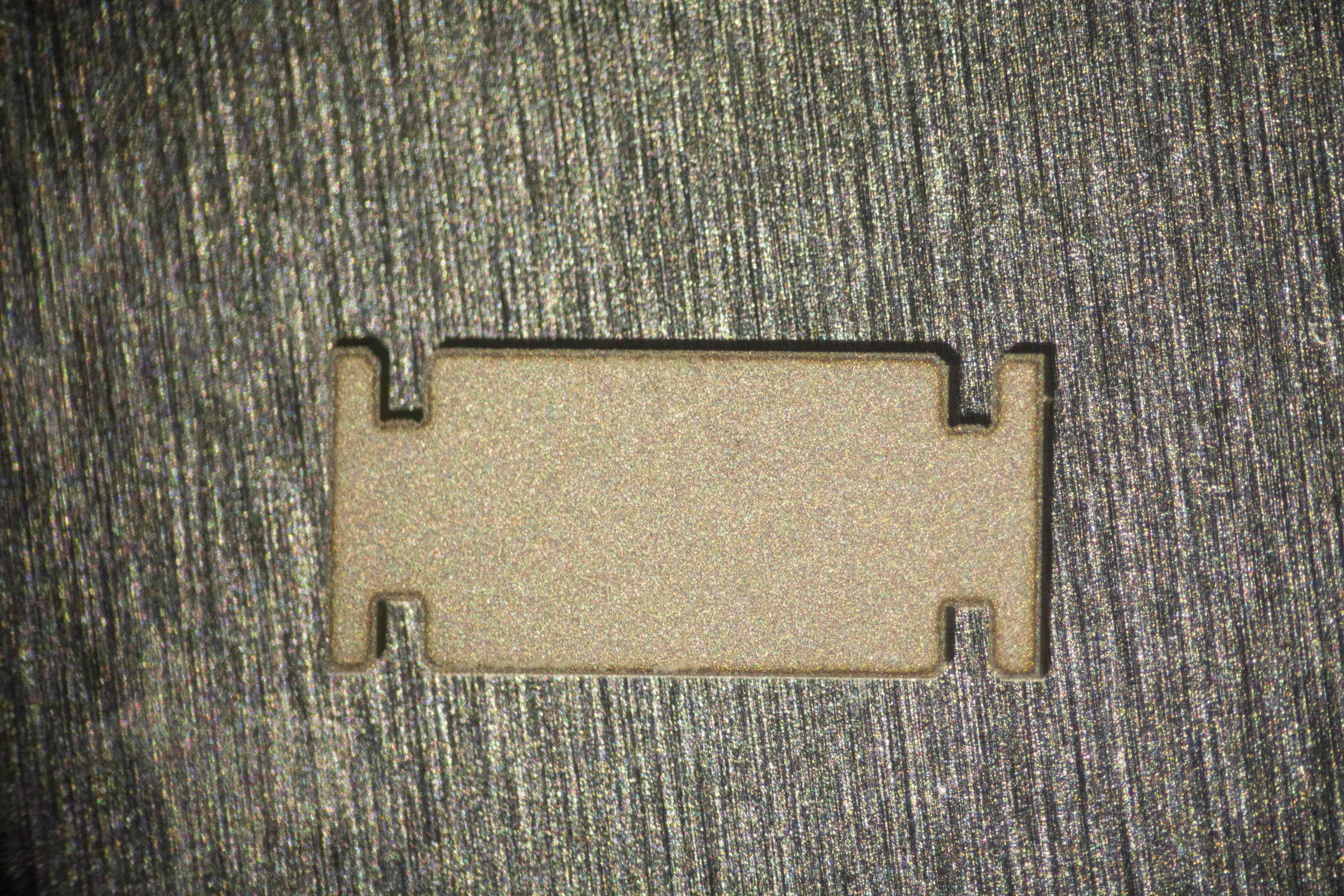

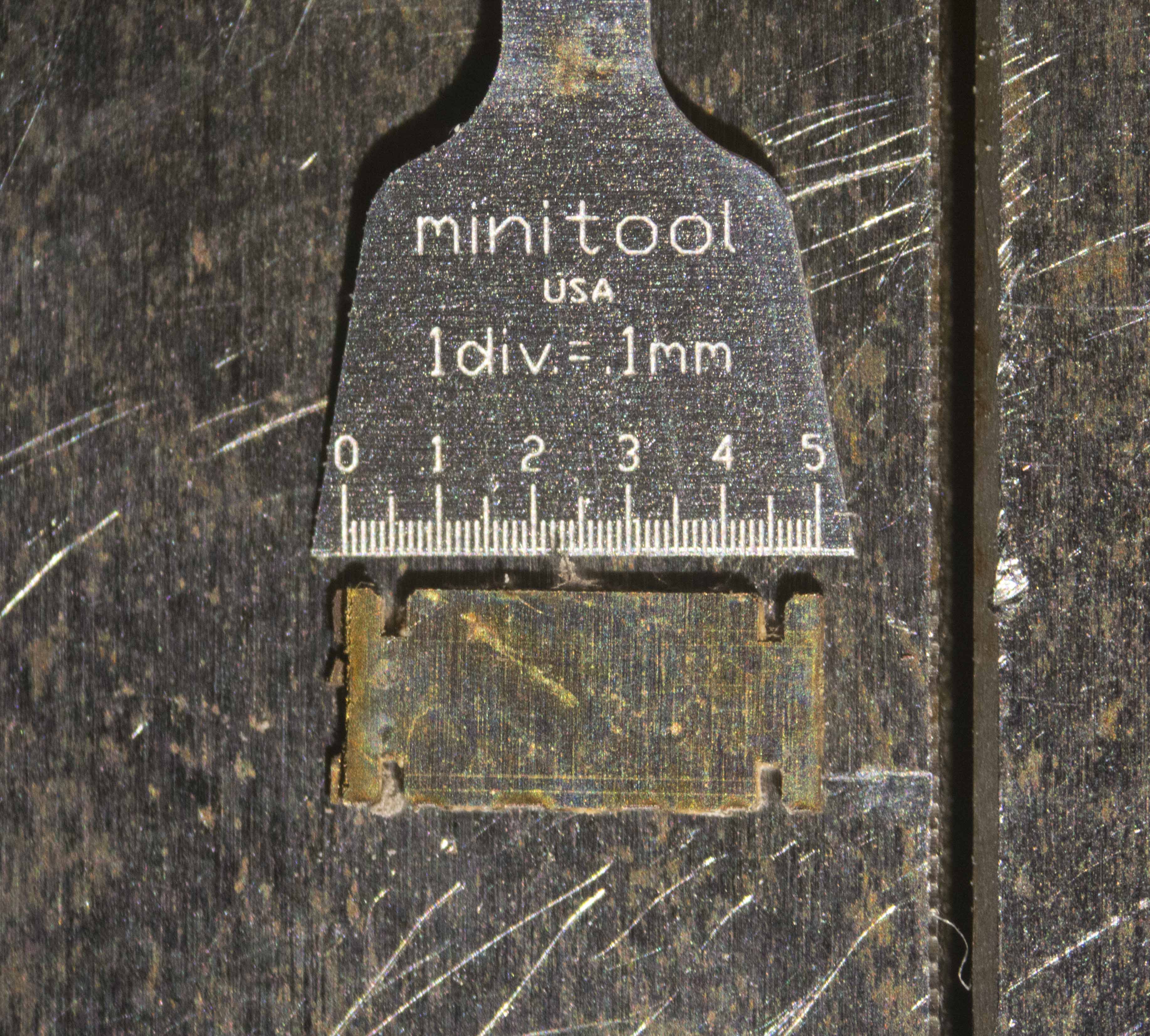

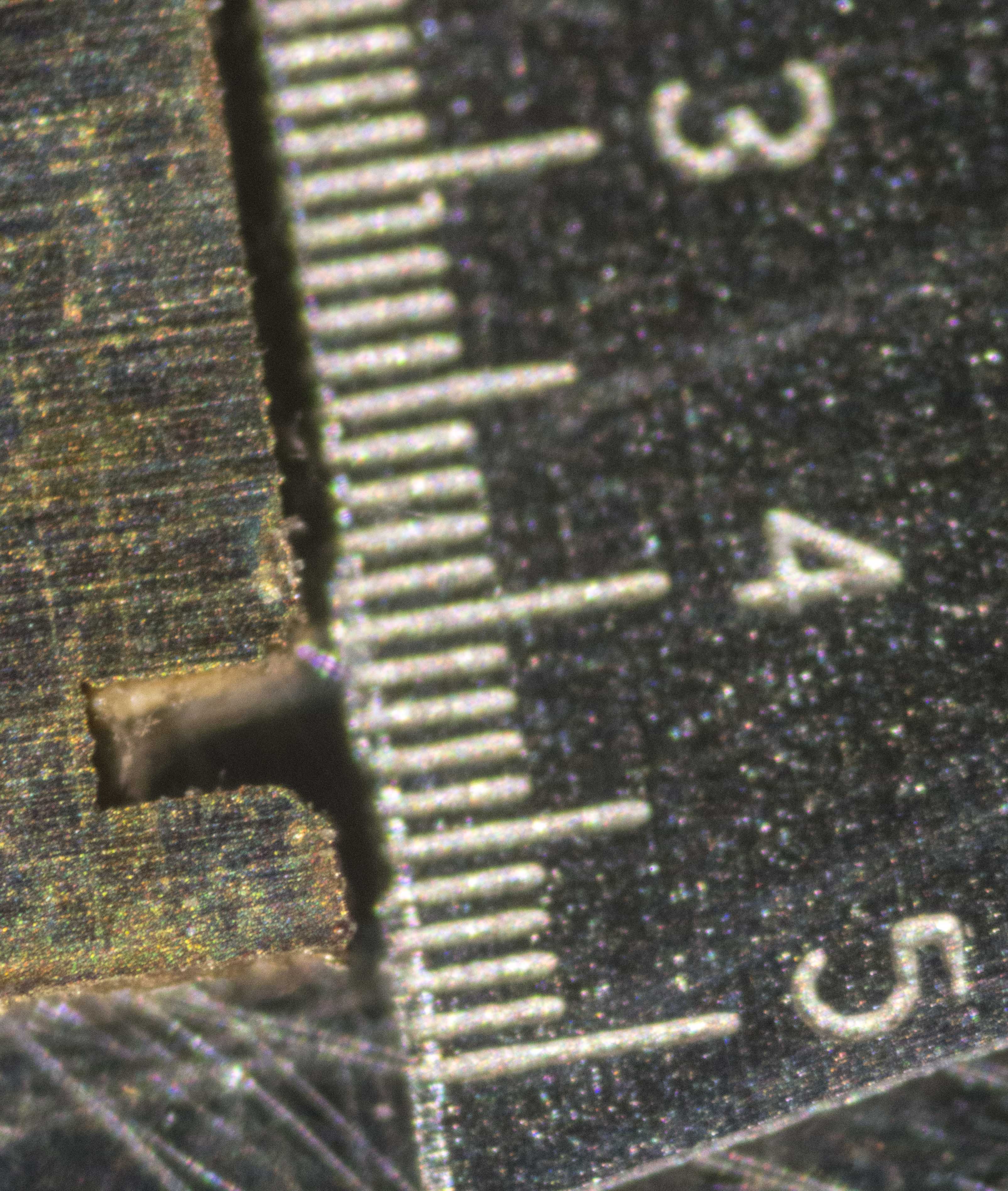

The part is 5mm in length. The slot width measures 275um (10.8 mil). The target slot width was 12mil so this is 1mil (25um) undersized.

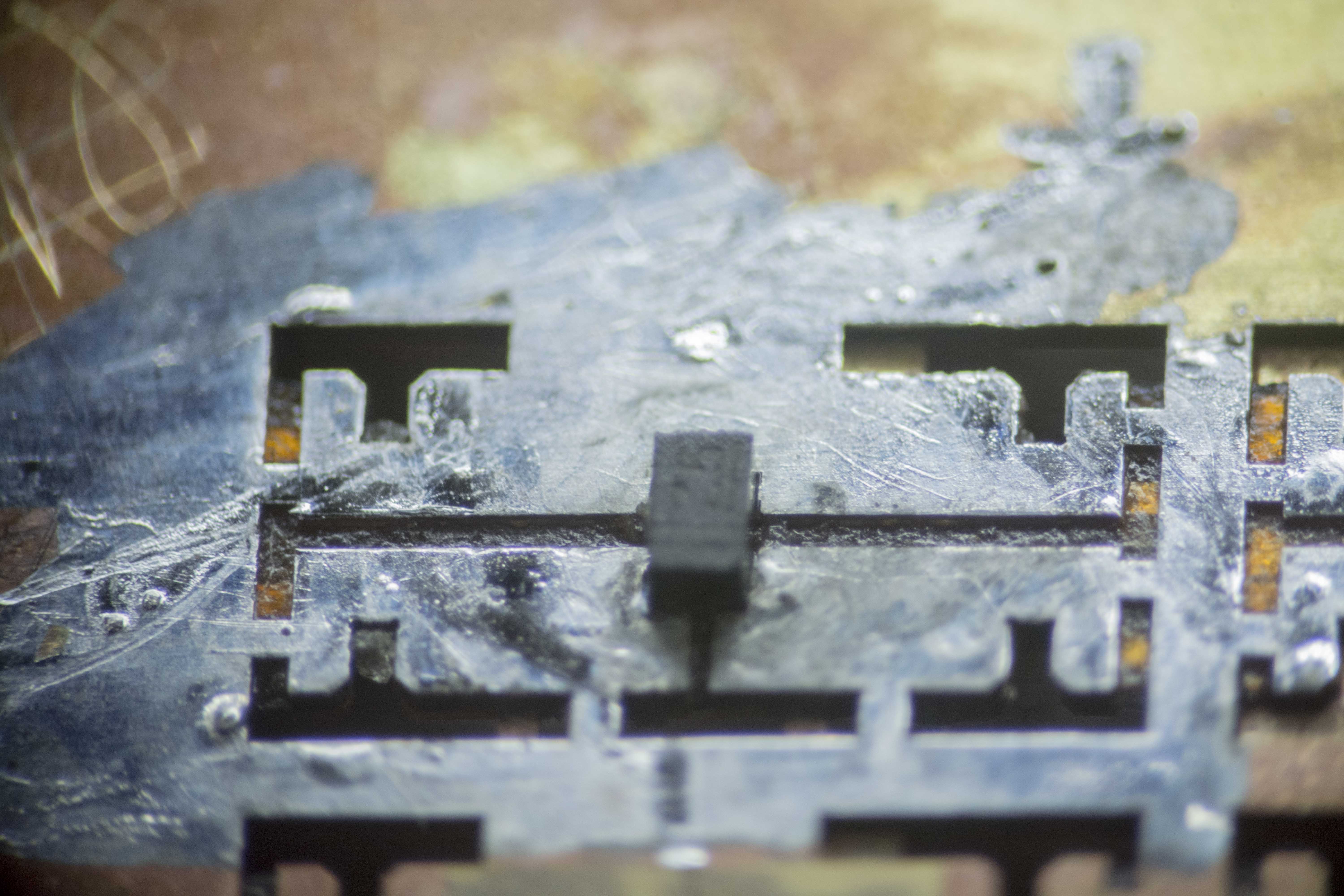

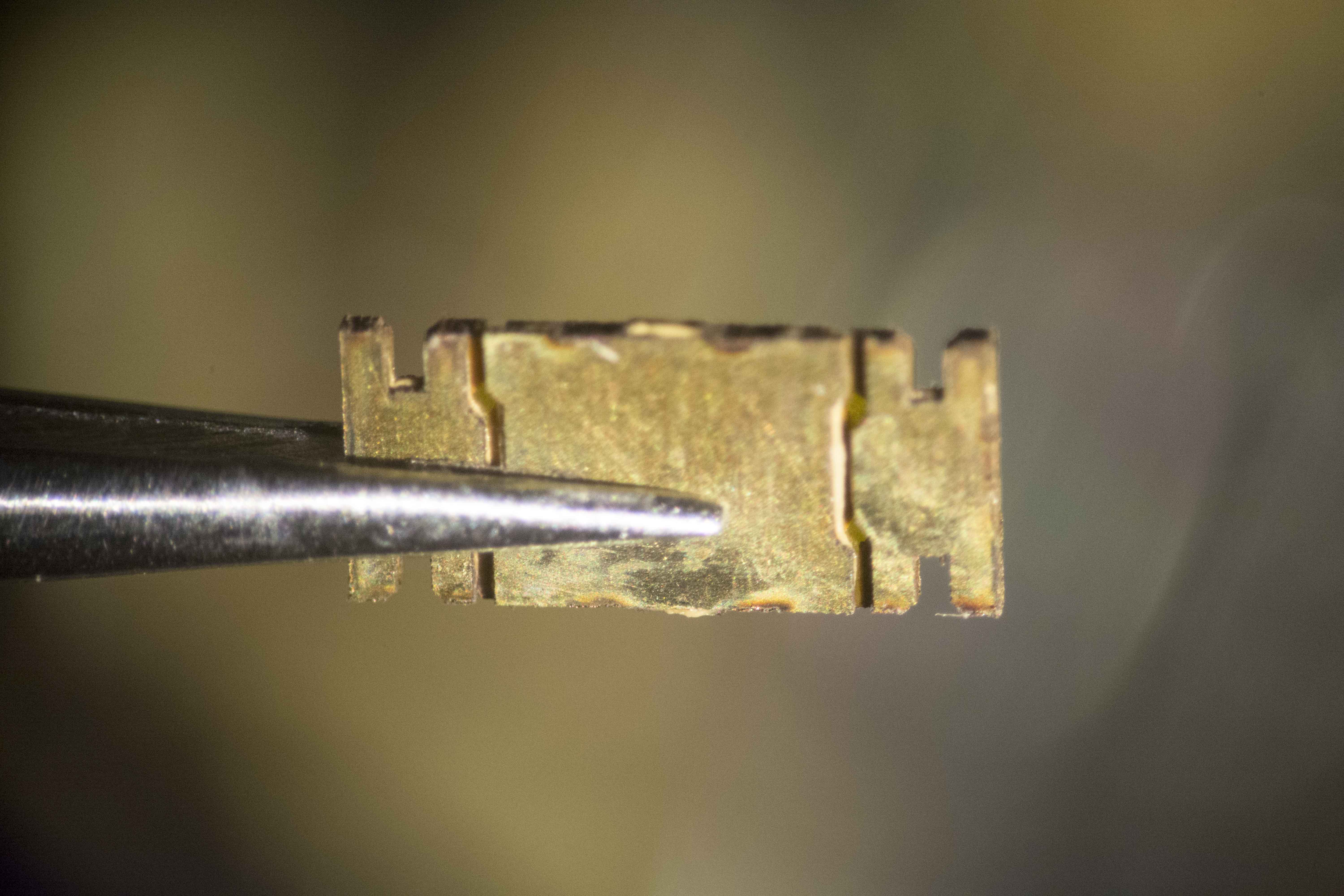

The joints can deform elastically in a large range, returning to their original position after being moved.